Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential WELDER INDUSTRIAL interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in WELDER INDUSTRIAL Interview

Q 1. What welding processes are you proficient in?

Throughout my career, I’ve become highly proficient in several welding processes. My expertise encompasses Gas Metal Arc Welding (GMAW), commonly known as MIG welding; Gas Tungsten Arc Welding (GTAW), or TIG welding; and Shielded Metal Arc Welding (SMAW), often called stick welding. I also have experience with Flux-Cored Arc Welding (FCAW), particularly useful for outdoor applications where shielding gas might be impractical. Each process offers unique advantages depending on the material, application, and desired weld quality. For instance, MIG welding is excellent for high-speed production, while TIG welding excels in precision work requiring a high-quality finish.

Q 2. Explain the difference between MIG and TIG welding.

MIG and TIG welding are both arc welding processes, but they differ significantly in their techniques and resulting weld characteristics. MIG welding uses a consumable electrode wire that continuously feeds into the weld pool, providing both filler material and electrical current. The shielding gas, usually Argon or a mixture of Argon and CO2, protects the weld from atmospheric contamination. It’s a faster process, ideal for mass production, but the weld puddle is often less controlled compared to TIG.

TIG welding, on the other hand, utilizes a non-consumable tungsten electrode to generate the arc. The filler metal is added separately, giving the welder more precise control over the weld puddle. TIG welding offers superior control, resulting in cleaner and more aesthetically pleasing welds, often necessary for critical applications. While slower than MIG, TIG welds generally exhibit greater strength and are better suited for thinner materials.

Think of it like this: MIG is like using a spray gun – fast and efficient, but less precise. TIG is more like using a fine brush – slower but capable of intricate detailing.

Q 3. Describe your experience with different welding filler metals.

My experience with filler metals spans a wide range of materials, tailored to specific applications and base metals. I’ve worked extensively with ER70S-6 for mild steel applications in MIG welding, known for its versatility and good weldability. For stainless steel, I frequently use filler metals such as 308L or 316L, depending on the specific grade and desired corrosion resistance. In TIG welding aluminum, I have experience with filler metals like 4043 and 5356, each offering different mechanical properties. Selecting the correct filler metal is critical for achieving the desired weld properties – strength, toughness, and corrosion resistance – and I always carefully consult material specifications before choosing a filler.

For example, in a project involving the repair of a stainless steel chemical tank, the correct choice of filler metal (316L in this case) ensured the weld maintained the same corrosion resistance as the original tank material. Incorrect choice could have led to premature failure.

Q 4. What safety precautions do you take while welding?

Safety is paramount in welding. My safety procedures are meticulous and consistently followed. This starts with proper Personal Protective Equipment (PPE), including a welding helmet with appropriate shade, flame-resistant clothing, gloves, and safety shoes. I always ensure adequate ventilation to prevent inhaling harmful fumes. Furthermore, I regularly inspect my equipment to ensure it’s in proper working order. This includes checking gas lines for leaks, ensuring proper grounding, and verifying the integrity of cables and electrodes. I also maintain a clean and organized workspace to minimize tripping hazards. Fire safety is also considered, keeping fire extinguishers readily accessible and knowing evacuation procedures. Before beginning any welding operation, I assess the area for flammables and take all necessary precautions.

Q 5. How do you ensure weld quality and consistency?

Ensuring weld quality and consistency involves a multi-faceted approach. Proper pre-weld preparation is key, including cleaning the base materials and selecting the right filler metal. During welding, maintaining consistent travel speed, arc length, and current is crucial. I regularly monitor the weld puddle to ensure proper penetration and fusion. Post-weld inspection is vital; I visually inspect welds for defects and use tools like a magnetic particle inspection (MPI) or dye penetrant testing (DPI) when necessary to detect subsurface defects. Documentation and traceability are essential, recording all parameters and materials used for future reference. Regular calibration of equipment and adherence to welding procedures are integral to maintain consistency and meet required standards.

Q 6. What are the common weld defects and how do you identify them?

Common weld defects include porosity (small holes in the weld), incomplete penetration (weld doesn’t fully fuse through the base material), lack of fusion (lack of bonding between weld and base metal), undercut (grooves along the weld bead), and cracks. Identifying these defects requires a keen eye and understanding of weld characteristics. Visual inspection is often the first step. However, more sophisticated methods such as radiographic testing (RT), ultrasonic testing (UT), or MPI are often necessary to detect internal flaws. For example, porosity can be identified visually as small pinholes, while incomplete penetration might show up as a lack of fusion in a cross-section. Understanding the cause of defects is crucial for preventing them in future welds. This may involve adjusting welding parameters, improving pre-weld preparation, or changing materials.

Q 7. Explain the importance of pre-weld preparation.

Pre-weld preparation is absolutely critical for achieving high-quality welds. This stage involves several crucial steps: First, thorough cleaning of the base materials is necessary to remove any contaminants such as rust, paint, oil, or grease, which can negatively affect weld quality and strength. The surfaces must be properly prepared by grinding, brushing, or other appropriate methods to ensure clean metal-to-metal contact. The correct joint design, fit-up, and clamping are also critical to ensure proper alignment and penetration. For example, in a butt weld, ensuring proper alignment of the two pieces of metal is critical to prevent lack of fusion. Finally, preheating the base metal might be necessary for certain materials, such as thicker sections or those with high carbon content, to reduce the risk of cracking and ensure better weld penetration.

Q 8. Describe your experience with different types of welding joints.

Welding joints are the way we connect two or more pieces of metal. My experience encompasses a wide range of these, categorized by their geometry and the resulting weld’s strength. Think of them like puzzle pieces – you need the right fit and technique for a strong, reliable bond.

- Butt Joints: These are the simplest, where two pieces are butted directly against each other. I’ve extensively used these in pipeline construction, requiring precise alignment and often pre-heating for larger sections. The challenge is ensuring full penetration of the weld.

- Lap Joints: One piece overlaps the other. I’ve applied this frequently in sheet metal work and fabrication, where ease of assembly is prioritized. The strength depends heavily on the overlap and weld size.

- T-Joints: One piece intersects another at a 90-degree angle. Common in structural steel, these demand careful control to avoid undercut and ensure complete fusion at the intersection.

- Corner Joints: Two pieces meet at a corner, often forming an ‘L’ shape. These are prevalent in frameworks and require meticulous technique to avoid porosity and maintain a uniform bead.

- Edge Joints: Two edges are welded together, often using a fillet weld. I’ve utilized this extensively in joining thinner sheets, where control of heat input is crucial to prevent burn-through.

Each joint type demands a specific welding process and technique for optimal results. For example, a butt joint in thick steel might need a multi-pass weld with pre-heating, while a thin sheet metal lap joint could be done with a single pass using a lower current.

Q 9. How do you interpret welding symbols?

Welding symbols are a standardized language for communicating weld requirements on engineering drawings. They are essential for ensuring that the weld is made correctly and to specification. Think of them as a concise, graphical instruction manual for the welder.

I’m proficient in interpreting these symbols, understanding the various components like:

- Reference Line: Indicates the location of the weld on the drawing.

- Arrow Side: The side of the joint where the symbol is placed.

- Other Side: The opposite side of the joint. Symbols will indicate if both sides are to be welded.

- Weld Symbols: These specify the type of weld, size, length, and other details (e.g., fillet weld, groove weld, etc.).

- Supplementary Symbols: These provide additional instructions, such as the weld type, contour, or finishing requirements (e.g., concave, convex, etc.).

For instance, a symbol might show a ‘>’ indicating a fillet weld on the arrow side only, with a dimension indicating its size and length, potentially alongside a symbol indicating the weld needs to be ground flush.

Misinterpreting these symbols can lead to costly mistakes and potential safety hazards, so thorough understanding is crucial.

Q 10. What is your experience with blueprint reading and welding specifications?

Blueprint reading and understanding welding specifications are fundamental skills for any professional welder. It’s like deciphering a map to build a structure of metal.

My experience includes interpreting a wide range of blueprints, from simple fabrication drawings to complex structural steel designs. This includes:

- Identifying weld locations and types: Using the aforementioned welding symbols.

- Understanding material specifications: Determining the appropriate welding process and parameters based on the material’s properties (e.g., steel grade, thickness).

- Interpreting dimensions and tolerances: Ensuring the final weld meets the required dimensional accuracy.

- Identifying surface finish requirements: Determining the level of post-weld finishing required (e.g., grinding, cleaning).

I’ve worked with AWS (American Welding Society) D1.1 Structural Welding Code and other relevant specifications, ensuring compliance and producing welds that meet the highest quality standards. I’ve found that careful cross-referencing of the blueprint and the materials list alongside the welding specifications is key to success. One project involved creating a complex steel support bracket – accurately interpreting the blueprint, understanding material specifications and weld requirements were crucial to its structural integrity.

Q 11. How do you troubleshoot welding equipment malfunctions?

Troubleshooting welding equipment is a critical skill, preventing costly downtime and ensuring safety. It’s like being a mechanic for your welding machine.

My approach to troubleshooting involves a systematic process:

- Safety First: Always disconnect power before inspection.

- Visual Inspection: Check for obvious problems like loose connections, damaged cables, or gas leaks.

- Check Power Supply: Ensure the power is sufficient and the voltage is correct.

- Gas Supply (for GMAW/GTAW): Verify the gas flow rate and pressure using gauges. Check for leaks using soapy water.

- Electrode/Wire Feed (for SMAW/GMAW): Inspect for kinks, proper feeding, and correct wire/electrode diameter.

- Ground Connection: Ensure a good clean ground connection to prevent poor welds or arc instability.

- Test the Arc: Attempt a test weld to isolate the problem.

For example, if you experience inconsistent arc, it could be due to a faulty ground connection, insufficient power, or a contaminated electrode. By systematically checking each component, the issue can usually be quickly identified and resolved.

Q 12. Describe your experience with different types of welding machines.

My experience spans various welding machines, each suitable for different applications. Think of them as specialized tools, each with its own strengths.

- Shielded Metal Arc Welding (SMAW): Commonly known as stick welding, this is versatile and portable but requires more skill due to its manual nature. I’ve extensively used SMAW for field repairs and outdoor construction.

- Gas Metal Arc Welding (GMAW): Also called MIG welding, it’s faster and produces cleaner welds than SMAW. It is my go-to method for production work involving sheet metal or large-scale fabrication.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding, it excels in producing high-quality, precise welds on thin materials. I’ve used GTAW for projects requiring exceptional precision and aesthetic finish.

- Flux-Cored Arc Welding (FCAW): A versatile process suitable for outdoor applications, providing good penetration and ease of use. I have found it useful in environments where shielding gas isn’t readily available.

My understanding extends beyond just operation; I can perform routine maintenance and troubleshoot issues on each of these machines. The selection of the appropriate machine and parameters is crucial for producing high-quality welds in a specific application. Choosing the wrong process can result in sub-par welds or even dangerous situations.

Q 13. What is your experience with non-destructive testing (NDT) methods?

Non-destructive testing (NDT) is crucial for ensuring weld integrity and safety. It’s like a thorough medical checkup for your welds, without causing damage.

My experience includes several common NDT methods:

- Visual Inspection (VT): A basic but essential method to detect surface defects. I always start with visual inspection before any other method.

- Magnetic Particle Inspection (MPI): Detects surface and near-surface cracks in ferromagnetic materials. I use this method to check for cracks in welds after the welding process is complete.

- Dye Penetrant Inspection (DPI): Detects surface-breaking defects in all materials, including non-ferromagnetic materials. This is crucial for finding minute surface flaws.

- Ultrasonic Testing (UT): Uses high-frequency sound waves to detect internal flaws. I use this for larger components or where internal defects are suspected.

Understanding the limitations of each method is as important as knowing how to perform them. For example, UT is excellent for detecting internal flaws but might not identify very small surface cracks. Using a combination of methods ensures comprehensive testing and increased confidence in the integrity of the weld.

Q 14. What is your experience with robotic welding?

Robotic welding offers significant advantages in terms of speed, consistency, and precision, especially for repetitive tasks. It’s like having a highly skilled, tireless assistant.

My experience with robotic welding involves:

- Programming and setup: I have programmed industrial robots using various programming languages and software to execute complex welding procedures. This involves setting the welding parameters, creating the robot’s path, and ensuring proper integration with the welding equipment.

- Operation and maintenance: I understand how to operate robotic welding systems, including troubleshooting and performing routine maintenance to maximize efficiency and minimize downtime.

- Fixture design and selection: Proper fixturing is critical for successful robotic welding; it ensures accurate part positioning and consistent weld quality. I possess the knowledge to determine what type of fixture design best suits a given application.

- Quality control: Even with robots, quality checks are essential. I have experience analyzing robot weld quality, optimizing welding parameters for consistent weld quality, and implementing statistical process control (SPC) techniques for continuous improvement.

Robotic welding significantly increased production efficiency and repeatability on a project involving welding car chassis parts. The consistent quality of the robotic welds significantly reduced the reject rate compared to manual welding.

Q 15. How do you maintain your welding equipment?

Maintaining welding equipment is crucial for safety, efficiency, and producing high-quality welds. My routine involves several key steps. First, I always visually inspect the equipment before each use, checking for any damage to cables, hoses, torches, and the welding machine itself. This includes looking for cracks, frayed wires, or leaks. Second, I meticulously clean the equipment after every use. This involves removing any spatter, slag, or debris from the torch, work area, and the machine’s exterior. For gas-based welding, I carefully check for leaks using a leak detector and ensure all gas cylinders are properly secured and capped when not in use. Regular maintenance includes changing consumables like welding tips and contact tips as needed, and lubricating moving parts according to the manufacturer’s recommendations. Finally, I keep detailed records of all maintenance performed, including dates, procedures, and any parts replaced. Think of it like servicing a car – regular checks and preventative maintenance prevent costly repairs down the line and ensure safe operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with different types of metals.

My experience encompasses a wide range of metals, including mild steel, stainless steel, aluminum, and various alloys. Working with mild steel is commonplace in structural applications, requiring a solid understanding of proper weld parameters to achieve good penetration and avoid porosity. Stainless steel presents unique challenges due to its susceptibility to oxidation and the need for specific filler metals and shielding gases to prevent discoloration. Aluminum, with its low melting point and high thermal conductivity, necessitates precise control of heat input to prevent burn-through. I’ve also worked extensively with various alloys, each demanding specific techniques and knowledge of their material properties to achieve optimal weld quality. For example, working with high-strength low-alloy steels requires meticulous attention to preheating and post-weld heat treatment to ensure proper mechanical properties. Each metal demands a unique approach based on its properties and the intended application.

Q 17. What are the different types of welding gases and their applications?

Several gases are used in welding, each serving a specific purpose. Shielding gases protect the weld pool from atmospheric contamination, ensuring a clean, sound weld. Common shielding gases include Argon (Ar), Helium (He), Carbon Dioxide (CO2), and mixtures like Argon-CO2. Argon is often used for welding aluminum and stainless steel because of its inert nature and ability to provide excellent arc stability. Helium is also used in some instances where a higher heat input is required, though it’s more expensive. CO2 is commonly used in MIG welding of mild steel, offering good penetration but potentially leading to more spatter. The choice depends heavily on the metal being welded and the welding process used. For example, Gas Metal Arc Welding (GMAW) or MIG welding uses shielding gases to protect the weld from atmospheric contamination, whereas Gas Tungsten Arc Welding (GTAW) or TIG welding commonly utilizes pure Argon or Argon-Helium mixtures to create a clean and precise weld. In addition to shielding gases, other gases like acetylene are used in oxy-fuel welding, providing the heat for fusion.

Q 18. What is your understanding of the AWS D1.1 structural welding code?

The AWS D1.1 Structural Welding Code is a comprehensive standard outlining requirements for structural welding. It provides detailed specifications for weld types, procedures, welder qualifications, and inspection criteria to ensure the structural integrity and safety of welded components. My understanding of this code goes beyond simply reading it; I actively apply its principles in my daily work. This includes selecting the appropriate welding procedure specification (WPS) based on the materials and design requirements, ensuring the correct welder qualifications are in place, and meticulously following the outlined procedures to produce sound welds. A key aspect is understanding the code’s requirements for pre-qualification of welding procedures, welder performance qualifications, and non-destructive testing (NDT) methods. The AWS D1.1 is critical for building safe and reliable structures, and my familiarity with it ensures adherence to industry best practices.

Q 19. Explain the importance of proper shielding gas coverage.

Proper shielding gas coverage is paramount for preventing weld defects. Shielding gas forms a protective blanket around the weld pool, preventing atmospheric contaminants like oxygen and nitrogen from reacting with the molten metal. These contaminants can cause porosity (tiny holes in the weld), oxidation, and other defects that compromise the weld’s strength and integrity. Imagine trying to cook a delicate dish without a lid – the unwanted elements could contaminate it. Similarly, insufficient shielding gas coverage can lead to compromised welds. Factors influencing coverage include gas flow rate, nozzle-to-workpiece distance, and the presence of drafts or wind. Ensuring adequate gas flow rate, using the right type of shielding gas for the base metal, and maintaining a consistent distance between the nozzle and workpiece are crucial for maximizing shielding gas effectiveness. Incorrect coverage can result in costly rework or even catastrophic failure.

Q 20. How do you ensure proper penetration and fusion in your welds?

Achieving proper penetration and fusion requires a combination of factors. Penetration refers to the depth of the weld, ensuring it fully penetrates the base materials being joined. Fusion refers to the complete melting and intermingling of the base metal and the filler metal, creating a strong metallurgical bond. To ensure both, I carefully adjust welding parameters like current, voltage, travel speed, and shielding gas flow rate. I also use appropriate filler metals and select the correct welding process based on the materials being welded and the joint design. Visual inspection plays a crucial role, ensuring that the weld bead exhibits proper shape and size. For deeper welds, I might utilize techniques like preheating the base materials to reduce thermal stress and prevent cracking. Furthermore, I often utilize non-destructive testing (NDT) methods, such as radiography or ultrasonic testing, to verify the internal integrity of the weld and ensure complete penetration and fusion. Consistent monitoring and adjustment of parameters are critical to ensure quality.

Q 21. How do you calculate the required weld size?

Calculating the required weld size is a critical step in structural welding and involves several factors. The weld size is determined based on the design loads, the material strength, and the type of joint being welded. This often involves using engineering calculations and referring to relevant welding codes like AWS D1.1. The calculations consider the tensile strength of the base material, the expected load on the weld, and the weld’s expected strength (based on the weld metal’s properties and the size of the weld). These calculations result in a required weld throat size, which then determines the weld leg size. For instance, a larger weld size will be required for a joint subjected to higher stress levels. Many professional welding programs will utilize software or detailed reference tables to determine the correct weld size; however, understanding the fundamental principles of strength of materials and the relevant welding codes is critical.

Q 22. Describe your experience with different types of welding electrodes.

My experience with welding electrodes is extensive, encompassing a wide range of materials and applications. I’m proficient with electrodes categorized by their coating type, which dictates their welding characteristics. For instance:

- E6010/E6011: These are cellulose-sodium electrodes ideal for all-position welding, especially in outdoor environments where fast-freezing is necessary. I’ve used these extensively on pipeline construction projects, appreciating their ability to weld in difficult-to-reach areas.

- E7018: Low-hydrogen electrodes, critical for high-strength steel applications requiring minimal porosity. I’ve employed these in pressure vessel fabrication where weld integrity is paramount.

- E6020: These are rutile electrodes offering excellent arc stability and slag removal. They are suitable for sheet metal work, and I utilized them extensively during automotive repair work early in my career, learning to appreciate their smooth weld bead.

- Stainless Steel Electrodes (e.g., 308L): I have significant experience with stainless steel electrodes, often utilizing them in food processing equipment manufacturing projects, understanding the critical need for corrosion resistance.

Beyond the common types, I’m comfortable selecting and applying specialized electrodes for specific alloys and applications, always ensuring the correct electrode is chosen for the material being welded.

Q 23. What is your experience with different types of welding power sources?

My experience with welding power sources includes both AC and DC systems, each suited to different welding processes and materials. I’m proficient with:

- AC Welding Machines: These are commonly used for general-purpose welding, offering simplicity and ease of use. I’ve used these for lighter gauge metals, such as aluminum.

- DC Welding Machines (Constant Current & Constant Voltage): DC welding machines are more versatile. Constant current machines are great for stick welding (SMAW), while constant voltage machines are crucial for MIG (GMAW) and TIG (GTAW) processes. I have extensive experience with both, regularly using them in various projects involving steel, stainless steel and aluminum.

- Inverters: Modern inverter technology provides better arc control and efficiency. I regularly use inverter-based machines for their portability and superior arc characteristics. I find this technology advantageous for working in tight spaces or on site.

Understanding the nuances of each power source and their settings – such as amperage and voltage – is critical to achieving high-quality welds. I always adjust these parameters to match the electrode, material and joint design for optimum penetration and minimal spatter.

Q 24. How do you manage multiple projects and priorities as a welder?

Managing multiple projects and priorities requires a structured approach. I utilize a system based on prioritization, meticulous planning, and effective time management. I start by identifying deadlines for each project, breaking them down into smaller, manageable tasks. I then prioritize tasks based on urgency and importance. I often employ tools like checklists and scheduling apps to stay organized. Communication is key; I maintain open communication with supervisors and colleagues to ensure clarity on expectations and potential roadblocks.

For example, I recently worked on three simultaneous projects: a large-scale structural steel project, smaller repairs on industrial machinery, and some custom metalwork for a local artist. By meticulously planning my time and prioritizing tasks based on deadlines, I successfully completed all three projects on time and to the client’s satisfaction. It’s all about careful planning and flexible adaptation.

Q 25. What is your experience with different types of welding positions?

Proficiency in various welding positions is essential for a versatile welder. I’m highly skilled in all common welding positions:

- Flat (1G): The easiest position, providing a strong base for learning fundamental techniques.

- Horizontal (2G): Requires control to prevent sagging of the weld pool.

- Vertical (3G): Demanding control and technique to manage the upward or downward flow of the molten metal.

- Overhead (4G): The most challenging position, demanding excellent control and precision.

My experience in various industries has required consistent work in all positions. Each requires distinct skills and techniques. I can adapt quickly to the demands of different positions, ensuring high-quality welds regardless of orientation.

Q 26. Describe a time you had to solve a welding problem.

During a recent project involving the repair of a large, cracked pressure vessel, I encountered significant challenges with consistent penetration. Initial welds showed inconsistencies and porosity. After careful examination, I identified the problem as insufficient preheating of the base metal, coupled with improper electrode selection. The incorrect electrode was not suitable for the thickness of the steel. I implemented several solutions:

- Proper Preheating: We established a preheating procedure to bring the base metal to the required temperature range before welding.

- Correct Electrode Selection: I switched to a low-hydrogen electrode (E7018) more suitable for thick sections and the high-strength steel. This provided better penetration and reduced porosity.

- Adjusting Welding Parameters: I optimized the amperage and arc length to ensure proper penetration and arc stability.

Through methodical troubleshooting and careful attention to detail, I successfully repaired the pressure vessel, ensuring its structural integrity and safety. This experience reinforced the importance of meticulous planning, adaptability and understanding material specifications.

Q 27. How do you stay current with the latest advancements in welding technology?

Staying current with welding advancements is crucial in this ever-evolving field. I actively pursue knowledge through several avenues:

- Industry Publications and Journals: I regularly read trade publications and journals to stay updated on new materials, processes and technologies.

- Professional Organizations: Membership in professional organizations like the American Welding Society (AWS) provides access to resources, training and networking opportunities.

- Online Courses and Webinars: Online platforms offer numerous courses and webinars on advanced welding techniques and technologies.

- Manufacturer Training: I participate in manufacturer-sponsored training programs to learn about new equipment and welding processes.

Continuous learning is vital, enabling me to adapt to new challenges and deliver high-quality work using the latest advancements.

Q 28. What are your salary expectations?

My salary expectations are commensurate with my experience, skill set, and the requirements of the position. Considering my extensive background and proven track record in complex welding projects, I am seeking a competitive salary within the range of $[Lower Bound] to $[Upper Bound] annually. This range reflects my value and contributions to a team.

Key Topics to Learn for a Welder Industrial Interview

- Welding Processes: Understanding different welding techniques (MIG, TIG, Stick, etc.), their applications, and limitations. Be prepared to discuss your experience with various processes and the materials they are best suited for.

- Blueprint Reading and Interpretation: Demonstrate your ability to accurately read and interpret welding symbols, dimensions, and tolerances on blueprints. Practice interpreting complex drawings and explaining your understanding.

- Weld Joint Design and Preparation: Discuss the importance of proper joint design and preparation for achieving strong, reliable welds. Be able to explain different joint types and their applications.

- Safety Procedures and Regulations: Highlight your knowledge of relevant safety standards and regulations (OSHA, etc.) related to welding. Discuss personal protective equipment (PPE) and safe welding practices.

- Quality Control and Inspection: Explain your understanding of weld quality inspection methods, including visual inspection, non-destructive testing (NDT) techniques, and the importance of adherence to quality standards.

- Troubleshooting and Problem Solving: Be ready to discuss how you approach troubleshooting welding defects, identifying root causes, and implementing corrective actions. Provide examples from your experience.

- Materials Science: Demonstrate a fundamental understanding of the properties of different metals and alloys commonly used in industrial welding (e.g., steel, aluminum, stainless steel).

- Welding Equipment and Maintenance: Discuss your experience with different welding equipment (power sources, torches, consumables) and basic maintenance procedures.

- Work Ethics and Teamwork: Emphasize your strong work ethic, ability to work effectively in a team, and adherence to deadlines and company policies.

Next Steps

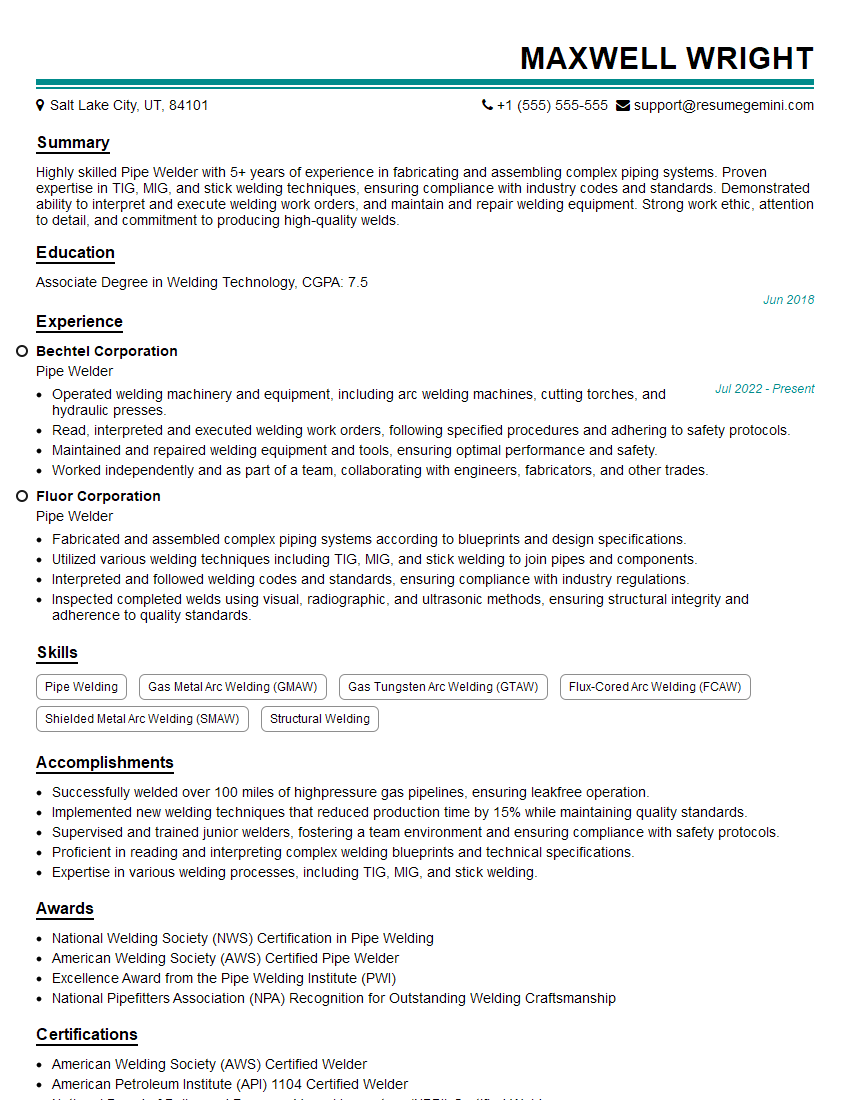

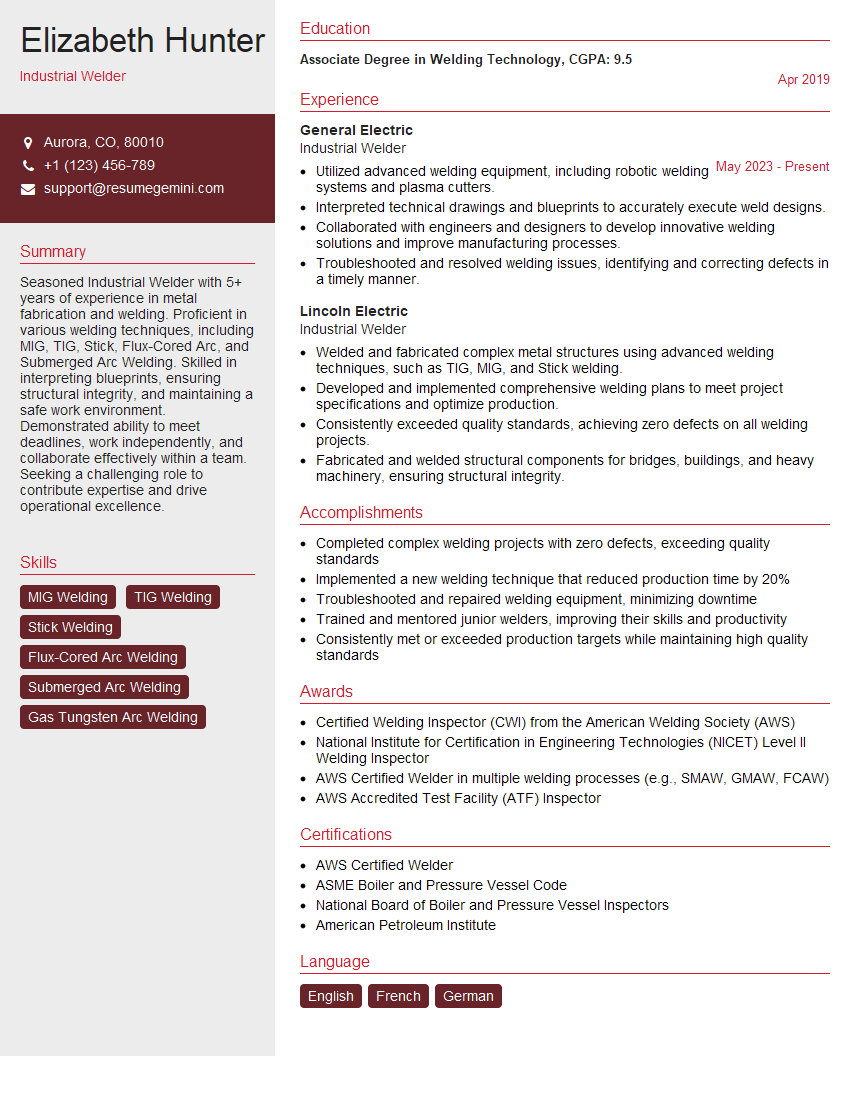

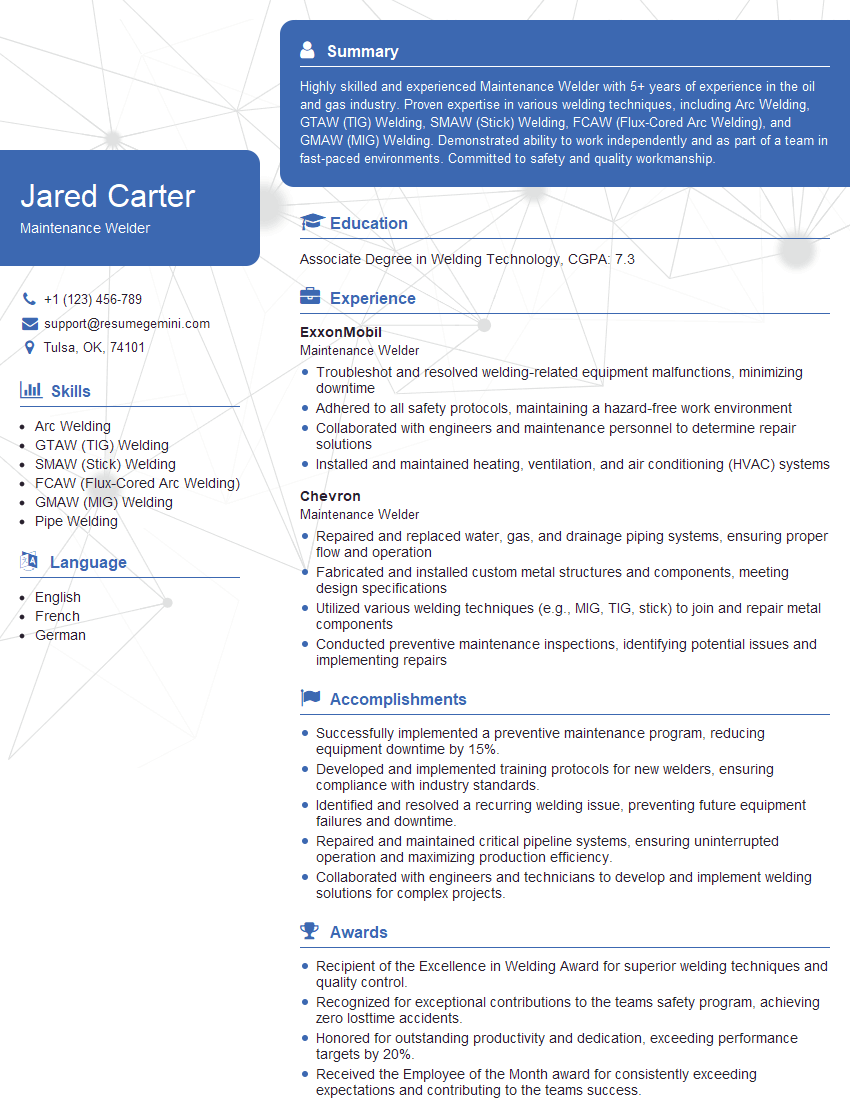

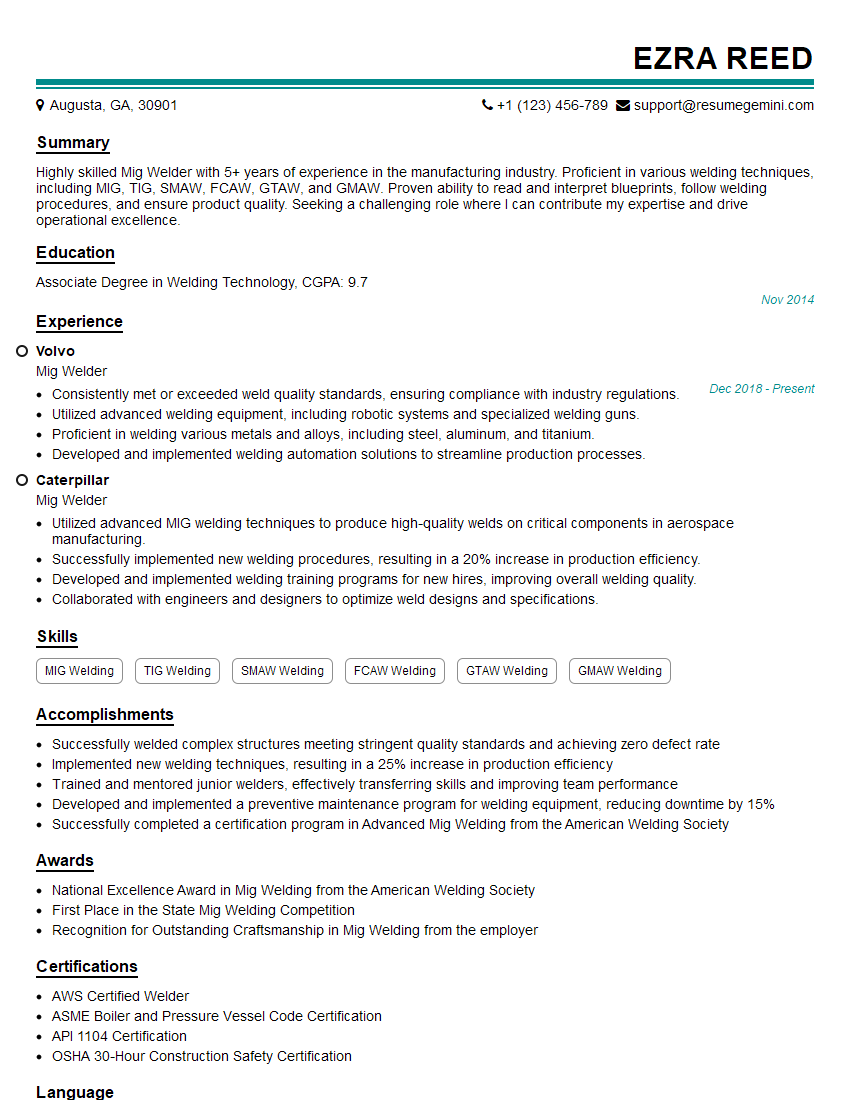

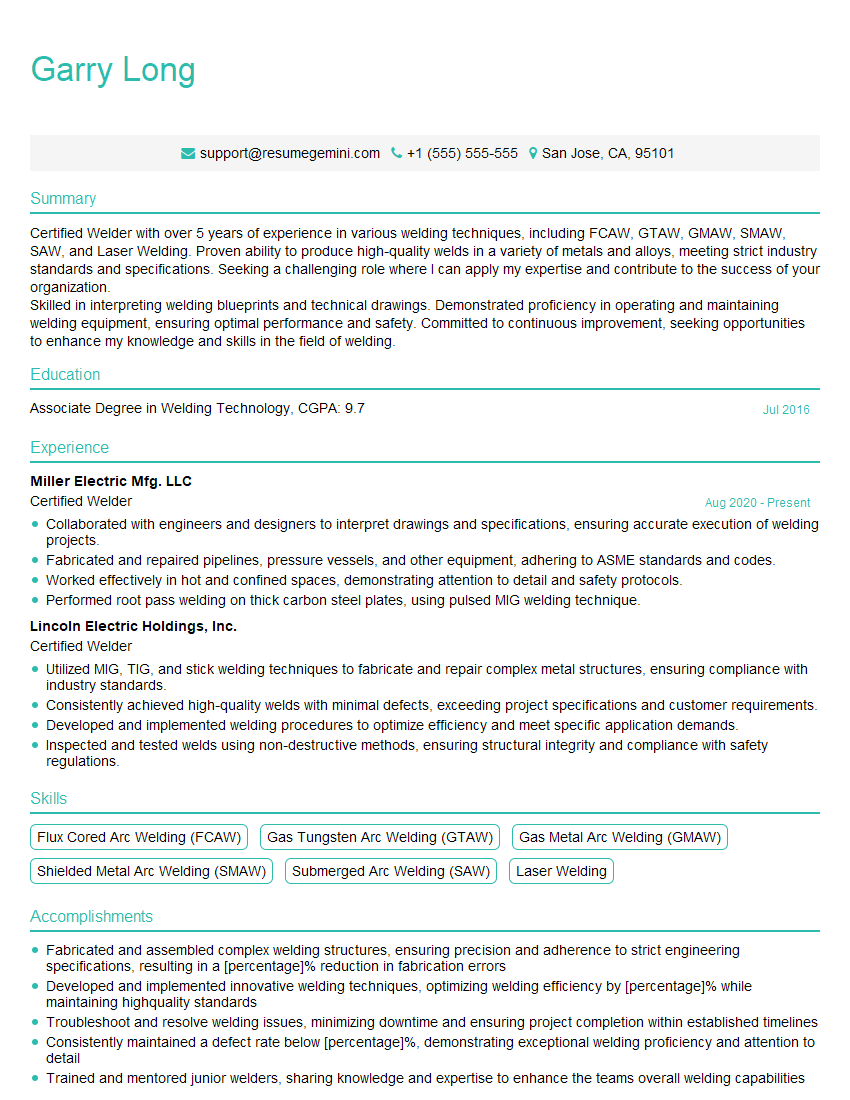

Mastering the skills and knowledge related to industrial welding is crucial for career advancement in this in-demand field. It opens doors to higher-paying positions, specialized roles, and increased job security. To maximize your chances of landing your dream job, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of industrial welding roles. Examples of resumes tailored to WELDER INDUSTRIAL positions are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO