The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Welding Machine Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Welding Machine Operation Interview

Q 1. What are the different types of welding processes?

Welding processes are broadly categorized by how they melt and fuse the base metals. There are numerous variations, but some of the most common include:

- Shielded Metal Arc Welding (SMAW or Stick Welding): Uses a consumable electrode coated with flux to protect the weld from atmospheric contamination. Think of it as a rudimentary, but very versatile, method.

- Gas Metal Arc Welding (GMAW or MIG Welding): Uses a continuously fed consumable wire electrode and a shielding gas (like Argon or CO2) to protect the weld. This is very efficient for high-volume work.

- Gas Tungsten Arc Welding (GTAW or TIG Welding): Uses a non-consumable tungsten electrode and a shielding gas to create a precise and high-quality weld. It’s ideal for thin materials and demanding applications.

- Flux-Cored Arc Welding (FCAW): Similar to MIG, but the electrode is a tubular wire filled with flux. This is often used outdoors where wind might disrupt a MIG process.

- Submerged Arc Welding (SAW): The arc is submerged under a blanket of granular flux, allowing for high deposition rates and deep penetration. Typically used for large-scale projects.

- Resistance Welding (Spot, Seam, etc.): Uses electrical resistance to heat and fuse metals together. Commonly used in automotive manufacturing for joining sheet metal.

Each process has its own strengths and weaknesses, making it suitable for different applications based on factors like material, thickness, accessibility, and required weld quality.

Q 2. Explain the difference between MIG and TIG welding.

MIG and TIG welding are both arc welding processes, but differ significantly in their technique and applications. Think of it like this: MIG is a ‘fast and efficient’ welder, while TIG is a ‘precise and meticulous’ welder.

- MIG (Gas Metal Arc Welding): Uses a consumable wire electrode that melts and becomes part of the weld pool. It’s faster, produces a wider bead, and is easier to learn, making it suitable for less demanding, high-volume applications. The shielding gas protects the weld puddle from oxidation.

- TIG (Gas Tungsten Arc Welding): Uses a non-consumable tungsten electrode to create the arc, and a separate filler rod is manually fed into the weld pool. It’s slower, produces a very clean and precise weld, and requires a higher skill level. Its precision is ideal for thinner materials, high-quality welds, and applications requiring a high degree of control.

In essence, MIG is about speed and efficiency, while TIG is about precision and quality. The choice depends heavily on the project requirements.

Q 3. Describe the safety precautions necessary when operating welding equipment.

Welding safety is paramount. Ignoring safety protocols can lead to severe burns, eye damage, respiratory problems, and even fire hazards. Here’s a comprehensive list:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including a welding helmet with the correct shade lens, welding gloves, long-sleeved clothing made of flame-resistant material, high-top safety boots, and hearing protection.

- Ventilation: Ensure adequate ventilation to remove welding fumes and gases. This could mean working in a well-ventilated area or using fume extraction systems.

- Fire Safety: Keep a fire extinguisher readily available and be aware of the surroundings to prevent fires. Remove any flammable materials from the welding area.

- Eye Protection: Never look directly at the welding arc without proper eye protection. Even brief exposure can cause severe and permanent eye damage.

- Skin Protection: Welding sparks and spatter can cause severe burns. Cover exposed skin completely.

- Proper Training and Certification: Ensure you’re properly trained and certified to operate the welding equipment before starting any work.

Remember, safety isn’t just about following rules; it’s about developing a safety-conscious mindset. A momentary lapse in concentration can have lasting consequences.

Q 4. How do you select the appropriate welding parameters (voltage, amperage, wire feed speed) for a given material and thickness?

Selecting the correct welding parameters is crucial for producing high-quality, sound welds. The parameters – voltage, amperage, and wire feed speed (for GMAW) – interact to determine the weld puddle characteristics.

There’s no single formula, as it varies greatly based on the material (steel, aluminum, stainless steel etc.), its thickness, and the welding process. However, here are some guiding principles:

- Material: Aluminum requires lower voltage and amperage than steel due to its lower melting point and higher thermal conductivity. Stainless steel may require specialized settings to prevent porosity.

- Thickness: Thicker materials generally require higher amperage and voltage to penetrate sufficiently. For example, welding a 1/4 inch steel plate needs significantly higher parameters than welding 1/8 inch steel.

- Welding Process: Each process has its optimal parameter ranges. MIG welding often uses lower voltage and higher amperage than TIG.

- Trial and Error (with safety precautions): Often, welders will use a “trial and error” method within a safe range of settings to achieve the desired weld bead profile and penetration. They might start with a recommended setting from the machine’s manual, then make small adjustments to optimize the weld.

Manufacturers often provide recommended parameter charts for different materials and thicknesses, serving as a valuable starting point. Consult these charts for your specific application and always prioritize safety.

Q 5. What are the common welding defects and how can they be prevented?

Several common welding defects can compromise the weld’s strength and integrity. Knowing these defects and their causes is key to prevention.

- Porosity: Small holes or voids in the weld, often caused by gas entrapment or insufficient cleaning of the base metal. Prevention involves proper cleaning, using the correct shielding gas, and controlling arc length.

- Undercutting: A groove melted into the base material at the edge of the weld, reducing strength and causing stress concentration. Prevention involves proper travel speed, and maintaining appropriate amperage and arc length.

- Lack of Fusion: Incomplete fusion between the weld metal and the base material. This results from poor joint design, insufficient heat input, or contamination. Prevention involves proper joint preparation, correct parameter selection, and clean base materials.

- Lack of Penetration: Insufficient penetration of the weld into the base material. This is often due to low amperage or voltage. Prevention involves correct parameter selection.

- Spatter: Droplets of molten metal ejected from the weld pool. This is mostly an aesthetic issue but excessive spatter can compromise the weld. Prevention often involves adjustments to the welding parameters, especially wire feed speed (in MIG welding) and electrode angle.

- Cracks: Fractures within the weld or the heat-affected zone. These are usually caused by rapid cooling, improper preheating, or hydrogen embrittlement. Prevention includes preheating the materials in some cases, using correct cooling techniques and appropriate filler materials.

Regular visual inspection and, where appropriate, non-destructive testing (NDT) are crucial for detecting defects early. A quality control program is key for consistent weld quality.

Q 6. Explain the importance of proper joint preparation in welding.

Proper joint preparation is fundamental to producing strong, reliable welds. Think of it as building a foundation for a house – a weak foundation will lead to a weak structure. Joint preparation aims to create a consistent gap and surface geometry to facilitate good penetration and fusion.

Different joint designs (butt, fillet, lap, etc.) require specific preparation methods. Common steps include:

- Edge Preparation: The edges of the materials need to be bevelled or chamfered to ensure complete penetration. The angle and size of the bevel depend on the material thickness and welding process.

- Gap Control: Maintaining a consistent gap between the materials is crucial. An incorrect gap can lead to lack of fusion or excessive weld reinforcement.

- Surface Cleaning: The surfaces must be clean and free of oil, grease, paint, or other contaminants that might hinder fusion. Grinding, wire brushing, and chemical cleaning might be required.

- Fit-Up: Accurate alignment and proper fit-up of the parts are essential for good weld quality. Clamps, tack welds, or jigs can help achieve this.

Neglecting joint preparation can lead to several defects, including lack of fusion, poor penetration, and increased stress concentration. Time spent on proper preparation is an investment in the quality and reliability of the weld.

Q 7. How do you troubleshoot common welding machine problems?

Troubleshooting welding machine problems requires a systematic approach. Start with the simple issues before moving to more complex ones. Always prioritize safety – disconnect the power before any internal work.

Here’s a framework:

- Check Power Supply: Ensure that the power is connected and working correctly. Check the circuit breaker, fuses, and voltage.

- Inspect Consumables: For MIG/FCAW, check for a kinked or damaged wire. Ensure the shielding gas tank isn’t empty. For SMAW (Stick welding), check for a cracked or damaged electrode.

- Examine Connections: Look for loose or corroded connections on the cables, electrodes, and ground clamp. Clean or tighten them as needed.

- Check Gas Flow (MIG/TIG): Verify the shielding gas flow rate with a flow meter. A low flow rate can lead to porosity.

- Assess the Arc: Observe the arc’s stability and appearance. An unstable arc may indicate problems with voltage, amperage, or grounding.

- Consult the Manual: Refer to the welding machine’s manual for troubleshooting information specific to your equipment.

- Contact Support: If the problem persists, contact a qualified welding equipment technician or the manufacturer’s support team.

Systematic troubleshooting saves time and ensures the safe and effective operation of the equipment. Don’t guess; inspect and test!

Q 8. Describe your experience with different types of welding filler metals.

My experience with filler metals is extensive, encompassing a wide range of applications. Filler metals are essentially the materials that are added to the weld joint to create the weld itself. The choice of filler metal is crucial and depends heavily on the base metal being welded, the welding process used, and the desired properties of the final weld. For instance, I’ve worked with various types of stainless steel filler metals, each with different chromium and nickel compositions to match specific grades of stainless steel. I’m also proficient with aluminum filler metals, which require different techniques due to their tendency to oxidize rapidly. My experience extends to carbon steel filler metals, ranging from low-carbon to high-strength alloys, each requiring careful selection to ensure proper weld penetration and strength. I also have experience using specialized filler metals for applications like dissimilar metal welding, which necessitate filler metals that bridge the gap in properties between different base metals. This experience includes understanding the role of flux core, solid wire, and even the impact of alloying elements on the final weld’s characteristics.

For example, in a recent project involving the welding of high-strength, low-alloy steel, I meticulously selected a filler metal with a similar composition and tensile strength to ensure optimal performance and structural integrity of the finished product. Incorrect filler metal selection would have led to weak welds and potential failure.

Q 9. How do you interpret welding symbols on engineering drawings?

Interpreting welding symbols is a fundamental skill for any welder. Welding symbols, found on engineering drawings, provide concise instructions about the type of weld, its dimensions, location, and any specific requirements. The symbol itself is often located on a reference line, with the arrow pointing towards the location of the weld on the part. The symbol’s main body contains details such as the weld type (e.g., fillet weld, groove weld), the size of the weld, and its length. Supplementary symbols and designations indicate further specifics, such as the weld’s root opening, reinforcement height, and any required surface treatments.

For instance, a small triangle on the reference line could denote a specific type of groove weld preparation, while a number near the symbol would specify the weld’s size. A field weld versus a shop weld is also indicated. Understanding these nuances is paramount for accurate and safe welding. I regularly utilize these symbols in my daily work, ensuring that all welds are executed precisely according to the provided specifications. A misinterpretation could lead to structural weakness or even failure of the welded component.

Q 10. What is the purpose of a welding procedure specification (WPS)?

A Welding Procedure Specification (WPS) is a document that outlines the specific parameters required to produce a consistently high-quality weld. It’s a crucial part of quality control in welding and ensures repeatability and reliability of the welding process. A WPS details the exact procedures, settings, and materials needed for a particular welding job. This includes aspects like the type of welding process (e.g., MIG, TIG, SMAW), the type of filler metal, the preheat temperature (if required), the welding current, voltage, and travel speed. It also specifies the post-weld heat treatment, if any, and might include acceptance criteria for visual inspection, non-destructive testing (NDT), or mechanical testing.

Think of the WPS as a recipe for a perfect weld. Following a properly validated WPS ensures that every weld produced under that specification meets the required quality standards. Deviating from the WPS without proper justification and approval can result in compromised weld quality and safety hazards.

Q 11. What are the different types of welding electrodes and their applications?

Welding electrodes are the consumable materials used in various arc welding processes. They come in many types, each designed for specific applications. Shielded Metal Arc Welding (SMAW), commonly known as stick welding, utilizes coated electrodes. The coating provides shielding gas and flux, protecting the weld from atmospheric contamination and controlling the weld pool. Different coatings offer different properties, including increased penetration, better slag removal, and improved weld quality. For example, E6010 electrodes are known for their deep penetration and are often used in out-of-position welding. E7018 electrodes provide excellent mechanical properties and are favored for critical applications.

Gas Metal Arc Welding (GMAW), or MIG welding, uses solid or flux-cored wires as electrodes. Solid wires provide a cleaner weld and better control but may require shielding gas. Flux-cored wires offer greater portability since they incorporate their own shielding gas within the wire. Gas Tungsten Arc Welding (GTAW), or TIG welding, uses a non-consumable tungsten electrode and typically requires a separate filler metal rod. This process is known for its high-quality and precise welds, ideal for applications requiring excellent aesthetics and performance. The choice of electrode greatly impacts the quality, strength, and overall characteristics of the weld.

Q 12. How do you ensure the quality of your welds?

Ensuring weld quality is paramount and involves a multi-faceted approach. It starts with careful selection of materials, proper preparation of the base metal, and precise adherence to the Welding Procedure Specification (WPS). During the welding process, constant monitoring is key. I observe factors such as arc stability, weld penetration, and the formation of any cracks or porosity. Visual inspection after welding is a fundamental step, checking for any visible defects such as undercuts, excessive reinforcement, or lack of fusion.

Beyond visual inspection, I utilize various non-destructive testing (NDT) methods depending on the application’s criticality. These methods can include radiographic testing (RT) to detect internal flaws, ultrasonic testing (UT) for assessing weld thickness and integrity, and magnetic particle testing (MT) for detecting surface and near-surface cracks. Documentation of all procedures and test results is meticulously maintained as a crucial part of quality control. Any defects found are thoroughly investigated, and corrective actions are implemented to prevent recurrence. The focus is always on producing welds that meet or exceed the specified requirements for both safety and performance.

Q 13. What are your experience levels with various welding processes (MIG, TIG, Stick, etc.)?

I possess extensive experience across various welding processes. My proficiency in MIG welding (GMAW) is particularly strong, having used it extensively for high-volume production work on various materials, including carbon steel, stainless steel, and aluminum. I’m adept at adjusting parameters like wire feed speed, voltage, and shielding gas flow to achieve consistent weld quality. My TIG welding (GTAW) skills are equally proficient, allowing me to perform precise and aesthetically pleasing welds, particularly valuable for applications requiring clean finishes. I am also very experienced in Stick welding (SMAW), particularly useful for field work due to its portability. I have a good understanding of the nuances of each process and their respective strengths and weaknesses. This enables me to select the most appropriate technique for any given task.

For example, a recent project involved welding thin-gauge stainless steel components. The delicate nature of the material dictated using TIG welding to minimize distortion and heat input. In contrast, a different project, welding thicker steel plates in a remote location, made stick welding the more practical and efficient choice. My experience allows me to adapt my skills to the task at hand, making me a versatile and reliable welder.

Q 14. Explain the principle of arc length control in welding.

Arc length control is crucial in all arc welding processes as it significantly impacts the weld’s quality. The arc length refers to the distance between the electrode and the workpiece. An optimal arc length is essential for achieving proper penetration, bead shape, and stability.

Too short an arc length can lead to excessive heat input, causing weld spatter, porosity, and even burn-through. The electrode might stick to the workpiece. Conversely, too long an arc length results in insufficient heat input, leading to poor penetration, a wider weld bead, and a weak weld. Maintaining a consistent arc length requires skill and experience, often involving adjustments to welding parameters. The appropriate arc length is often visually determined through experience, or sometimes by using arc length control systems found in some modern welding machines. Some machines provide feedback to the operator such as audio or visual cues indicating arc length. Maintaining the correct arc length is essential for producing consistent, high-quality welds.

Q 15. How do you maintain and clean welding equipment?

Maintaining and cleaning welding equipment is crucial for safety, efficiency, and longevity. It’s like regularly servicing your car – preventative maintenance avoids costly repairs later. My routine involves several key steps:

- Daily Cleaning: After each welding operation, I remove spatter using a wire brush, chipping hammer (carefully!), or specialized spatter remover. I then clean the welding machine’s exterior with a damp cloth to remove dust and debris. For MIG/MAG welders, I inspect the wire feed mechanism for obstructions and clean the contact tip.

- Regular Inspections: I check all cables for damage, ensuring proper insulation and secure connections. Gas hoses are inspected for leaks and cracks, and I verify the regulator pressure gauges are accurate. I also visually inspect the welding torch for cracks, damage, and proper gas flow.

- Periodic Maintenance: This involves more involved tasks such as changing filters (air, gas, etc.), lubricating moving parts as per the manufacturer’s instructions, and checking the machine’s cooling system. For example, on a submerged arc welding (SAW) machine, I’d meticulously clean the flux hopper and ensure the flux is dry and free-flowing.

- Professional Servicing: Annual professional servicing is vital for complex machines. This ensures that internal components are checked, calibrated, and any potential issues are addressed proactively. This is comparable to taking your car for its annual MOT.

Thorough cleaning and maintenance not only extend the lifespan of the equipment but also contribute to producing high-quality welds and ensure a safer working environment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of welding power sources.

I have extensive experience with various welding power sources, including:

- AC/DC Transformers: I’ve worked with traditional transformer-based welders, understanding their characteristics, like higher open-circuit voltage for arc initiation, and how to adjust parameters for different applications and materials. For instance, using a higher current setting for thicker steel sections.

- Rectifiers: These provide a constant current output, better suited for certain processes like MIG and TIG welding. I’m experienced in understanding and troubleshooting rectifier issues, such as ripple and voltage drop.

- Inverter-based Machines: My experience also includes the latest inverter technology, which is lighter, more efficient and provides excellent arc control. I’m proficient in using their advanced features, like pulsed MIG welding, for improved control and weld quality. I understand how their power regulation differs from traditional transformers.

- Constant Current vs. Constant Voltage: I’m adept at choosing the appropriate power source based on the welding process. For example, constant current is essential for stick welding, while constant voltage is better suited for MIG welding.

My experience encompasses not only using these power sources but also diagnosing and troubleshooting problems related to their operation, ensuring optimal performance and weld quality.

Q 17. What are the different types of shielding gases used in welding?

Shielding gases are essential in many welding processes to protect the weld pool from atmospheric contamination, which can lead to porosity and reduced weld strength. The choice of shielding gas depends on the welding process and the material being welded. Common shielding gases include:

- Argon (Ar): Inert, widely used in TIG and MIG welding of aluminum and other non-ferrous metals. It provides excellent arc stability and penetration.

- Helium (He): Another inert gas, offering higher thermal conductivity than Argon, resulting in a hotter arc and faster welding speeds. Often used in TIG welding of stainless steel.

- Carbon Dioxide (CO2): Active gas, commonly used in MIG welding of steel. It’s less expensive than Argon but can produce more spatter.

- Argon/CO2 Mixtures: Commonly used in MIG welding, offering a balance between cost and weld quality. The mixture ratio is adjusted based on the material and desired weld characteristics.

- Other mixtures: Specific mixtures, such as Argon/Oxygen or Argon/Helium blends, are sometimes used for specialized applications depending on material and desired properties.

Understanding the properties of each gas and its effect on the weld is critical for successful welding. I am experienced in selecting the correct gas for each application and monitoring the gas flow to ensure consistent weld quality.

Q 18. How do you perform a visual inspection of a weld?

Visual inspection is the first and often most crucial step in weld quality assessment. It’s like a doctor’s initial examination, providing valuable clues before more advanced techniques are employed. My visual inspection typically involves:

- Weld Profile: Examining the weld bead’s shape, size, and consistency for any irregularities. A smooth, consistent bead suggests good weld quality, while excessive undercut, overlap, or porosity indicates potential issues.

- Surface Finish: Assessing the overall surface finish for cracks, porosity (small holes), slag inclusions (embedded debris), or spatter. A clean, smooth surface usually points to a well-executed weld.

- Root Penetration: Checking the penetration of the weld into the base materials (for joints). Insufficient penetration can result in weakness, so this is essential, particularly in critical welds. Methods for checking this vary from direct visual access (with appropriate magnification), to using specialized equipment for testing.

- Dimensions: Measuring the weld dimensions to ensure they comply with the specifications. The size and shape should match the design requirements.

Visual inspection is a critical first step that helps identify readily visible flaws. It guides further, more detailed testing if necessary.

Q 19. What are the limitations of different welding processes?

Every welding process has its strengths and weaknesses, limiting its applicability to certain materials and situations. For example:

- SMAW (Shielded Metal Arc Welding): Relatively inexpensive equipment, portable, but susceptible to atmospheric contamination and slower welding speeds, making it less ideal for high-speed production.

- MIG (Gas Metal Arc Welding): High deposition rates, versatile, good for various materials, but susceptible to spatter and requires more skill for achieving high-quality welds on thin materials.

- TIG (Gas Tungsten Arc Welding): Excellent control, high-quality welds, suitable for precise work and thin materials, but lower deposition rate and requires more skill and patience.

- SAW (Submerged Arc Welding): High deposition rates, excellent for thick materials and high-volume production, but less versatile and requires specific equipment and setup.

Understanding these limitations allows for selecting the most suitable process for the job, leading to better results and increased efficiency. I factor these limitations into every project I undertake.

Q 20. How do you handle different welding positions (flat, vertical, overhead)?

Welding in different positions (flat, vertical, overhead) requires adjustments in technique and equipment to maintain weld quality. My experience across these positions includes:

- Flat Position: The easiest position, allowing for a more natural weld bead formation. I focus on maintaining consistent travel speed and current.

- Vertical Position: Requires more control over the arc length and travel speed to prevent sagging or excessive penetration. I use techniques like stringer beads or weave beads as appropriate.

- Overhead Position: The most challenging position, demanding precise control and mastery of welding techniques. This requires advanced skills to prevent the weld pool from sagging and ensuring proper penetration. It involves careful control of travel speed, arc length, and electrode angle.

In each position, I adapt my technique to compensate for gravity and maintain a consistent, high-quality weld. For overhead welding, for example, I often use smaller diameter electrodes to minimize sag.

Q 21. Describe your experience with robotic welding systems.

I have significant experience working with robotic welding systems, including programming, setup, and troubleshooting. This includes experience with different robot manufacturers and controllers.

- Programming and Setup: I’m proficient in creating and modifying welding programs using industry-standard software. This includes defining weld parameters, robot path, and joint configurations. I understand the importance of precise programming for consistent weld quality and repeatability.

- Troubleshooting: I can diagnose and resolve issues that can occur with robotic systems, including mechanical problems, sensor errors, and software glitches. My troubleshooting skills include working with system diagnostics and identifying and rectifying errors.

- Process Optimization: I have experience optimizing robot welding processes to improve efficiency, reduce costs, and ensure consistent weld quality. This involves fine-tuning welding parameters, such as speed and voltage, based on real-time data and feedback.

Robotic welding offers superior consistency, speed and precision compared to manual welding, particularly in high-volume production. My experience encompasses all aspects of implementing and maintaining these sophisticated systems.

Q 22. What is your experience with non-destructive testing (NDT) of welds?

Non-destructive testing (NDT) is crucial for ensuring weld quality without damaging the base material. My experience encompasses various NDT methods, including visual inspection (the most fundamental), which I use to check for surface flaws like cracks, porosity, or undercut. I’m also proficient in magnetic particle inspection (MPI), ideal for detecting surface and near-surface defects in ferromagnetic materials. Ultrasonic testing (UT) is another technique I’ve employed to locate internal flaws by using high-frequency sound waves. Finally, I have experience with radiographic testing (RT), or X-ray inspection, which provides detailed images of internal weld structure and reveals hidden imperfections. The choice of NDT method depends on the specific application, material, and required level of detail. For instance, a simple fillet weld might only need visual inspection, while a critical pressure vessel weld might require RT and UT.

In practice, I meticulously document all NDT findings, following established procedures and standards. This ensures traceability and allows for accurate assessment of weld integrity. Any identified defects are carefully evaluated to determine their severity and the appropriate corrective action. I’m familiar with interpreting NDT results and understanding the acceptance criteria defined by relevant codes and standards, such as ASME Section IX.

Q 23. How do you ensure compliance with safety regulations in a welding environment?

Safety is paramount in a welding environment. My approach to ensuring compliance begins with a thorough understanding of all relevant safety regulations, including OSHA guidelines and any company-specific safety protocols. This includes proper use of Personal Protective Equipment (PPE), such as welding helmets with appropriate shade lenses, gloves, protective clothing, and safety footwear. I always check my equipment before each weld, making sure that everything is properly grounded and functioning correctly. This includes ensuring that cables are properly insulated and connected, and that ventilation is adequate to remove harmful fumes.

Beyond personal safety, I actively contribute to a safe work environment by maintaining a clean and organized workspace, ensuring clear access for others, and storing materials safely. I regularly participate in safety training and toolbox talks, and I’m always vigilant in identifying and reporting any potential hazards. I believe that proactive safety measures are far more effective and cost-efficient than reacting to accidents.

Q 24. Describe a situation where you had to solve a welding-related problem.

During a project involving the welding of stainless steel pipes for a pharmaceutical plant, I encountered significant difficulties with weld porosity. Initial welds showed excessive porosity, rendering them unacceptable. I systematically investigated the problem by reviewing the welding procedure specification (WPS), checking the cleanliness of the base material and filler metal, and verifying the shielding gas flow rate and purity.

After careful analysis, I discovered that the root cause was a combination of factors: insufficient purging of the interior of the pipes prior to welding and a slightly lower-than-specified shielding gas flow rate. By implementing corrective measures, including thorough pipe purging with inert gas and adjusting the gas flow rate, we eliminated the porosity issue. We also implemented improved pre-weld cleaning procedures. This experience highlighted the importance of meticulous attention to detail in welding, as seemingly minor factors can have a significant impact on the final product quality. The successful resolution not only ensured project completion but also reinforced the importance of problem-solving skills in my role.

Q 25. What is your experience with different types of base metals?

My experience encompasses a broad range of base metals, including carbon steels, stainless steels (austenitic, ferritic, and martensitic grades), aluminum alloys, and various other metals such as nickel alloys and titanium. Each metal presents unique welding challenges. Carbon steels are relatively easy to weld, but require appropriate pre-heating and post-weld heat treatment depending on the thickness. Stainless steels require more careful control of welding parameters to avoid issues like cracking or sensitization. Aluminum requires special techniques and filler materials because of its high thermal conductivity and tendency to oxidize. Working with these different materials requires selecting appropriate filler metals, adjusting parameters like current, voltage, and travel speed, and understanding the potential for post-weld heat treatment or other processes. For example, I have extensive experience welding 304 stainless steel using GTAW (Gas Tungsten Arc Welding) for high-purity applications, and MIG (Metal Inert Gas Welding) for carbon steel in structural projects.

Understanding the properties of each material—their melting points, thermal conductivity, susceptibility to cracking, and other characteristics—is crucial for producing high-quality welds. This knowledge allows me to choose the right welding process and adjust my techniques accordingly.

Q 26. How do you manage a welding project effectively?

Effective welding project management involves careful planning, execution, and monitoring. It starts with a thorough review of the project specifications, including blueprints, material lists, and welding procedures. This helps in accurately estimating time and resources required. Next, I create a detailed welding plan that outlines the sequence of operations, identifies potential challenges, and allocates tasks to the team, including myself if I’m leading the project.

During execution, I consistently monitor the progress, ensuring compliance with the welding procedures and safety regulations. Regular inspections and quality checks are integral parts of my process. This helps in identifying and resolving any issues promptly, preventing delays and ensuring that the final product meets the required quality standards. Clear communication with the project team and stakeholders is vital to keep everyone informed and manage any arising concerns. After completion, project documentation including inspection reports, NDT results and welding parameters are compiled for quality control and future reference. Using project management tools like Gantt charts and spreadsheets helps ensure efficiency.

Q 27. What are your career goals in the field of welding?

My career goals are focused on continuous professional development and expanding my expertise in the welding field. I aim to become a certified welding inspector, enhancing my ability to oversee complex projects and ensure the highest standards of quality and safety. I’m also interested in specializing in advanced welding techniques, such as robotic welding or laser welding. Longer-term, I aspire to take on a leadership role, mentoring younger welders and contributing to the overall advancement of welding practices within the industry. I believe my dedication, coupled with ongoing learning, will allow me to achieve these goals.

Q 28. What are your strengths and weaknesses as a welder?

One of my greatest strengths is my meticulous attention to detail. I believe that precision and accuracy are essential for producing high-quality welds. I’m also a highly effective problem-solver, capable of identifying and resolving issues efficiently. I’m a quick learner, eager to adopt new techniques and technologies. My experience shows consistent reliability and an ability to work independently or as part of a team.

One area I’m continuously working to improve is my public speaking skills. While I’m comfortable communicating within a team setting, I recognize the importance of clearly and confidently presenting technical information to larger audiences. I am actively addressing this by participating in professional development opportunities and seeking feedback on my communication style.

Key Topics to Learn for Your Welding Machine Operation Interview

Landing your dream welding job starts with thorough preparation. This section outlines key areas to focus on to impress your future employer.

- Welding Processes: Understanding different welding processes like MIG, TIG, SMAW, and their applications. Be ready to discuss the advantages and disadvantages of each, considering factors like material thickness and joint type.

- Machine Setup and Operation: Demonstrate your knowledge of setting up various welding machines, including adjusting parameters like voltage, amperage, and wire feed speed. Be prepared to explain how these settings affect the weld quality.

- Safety Procedures and Regulations: Safety is paramount in welding. Highlight your understanding of relevant safety regulations, personal protective equipment (PPE), and emergency procedures. This shows responsibility and commitment to workplace safety.

- Weld Quality Inspection and Testing: Explain your familiarity with inspecting welds for defects like porosity, cracks, and incomplete penetration. Discuss different testing methods used to assess weld strength and quality.

- Troubleshooting and Problem-Solving: Welding isn’t always perfect. Prepare examples showcasing your ability to identify and troubleshoot common welding problems, such as poor penetration, excessive spatter, or inconsistent arc length. Explain your diagnostic and corrective approaches.

- Material Science and Metallurgy: A foundational understanding of different metal types, their properties, and how they behave during welding is crucial. This includes understanding issues like heat-affected zones and potential metallurgical changes.

- Blueprint Reading and Interpretation: Demonstrate your ability to interpret welding symbols and blueprints to understand the required weld specifications and procedures.

Next Steps: Secure Your Welding Future

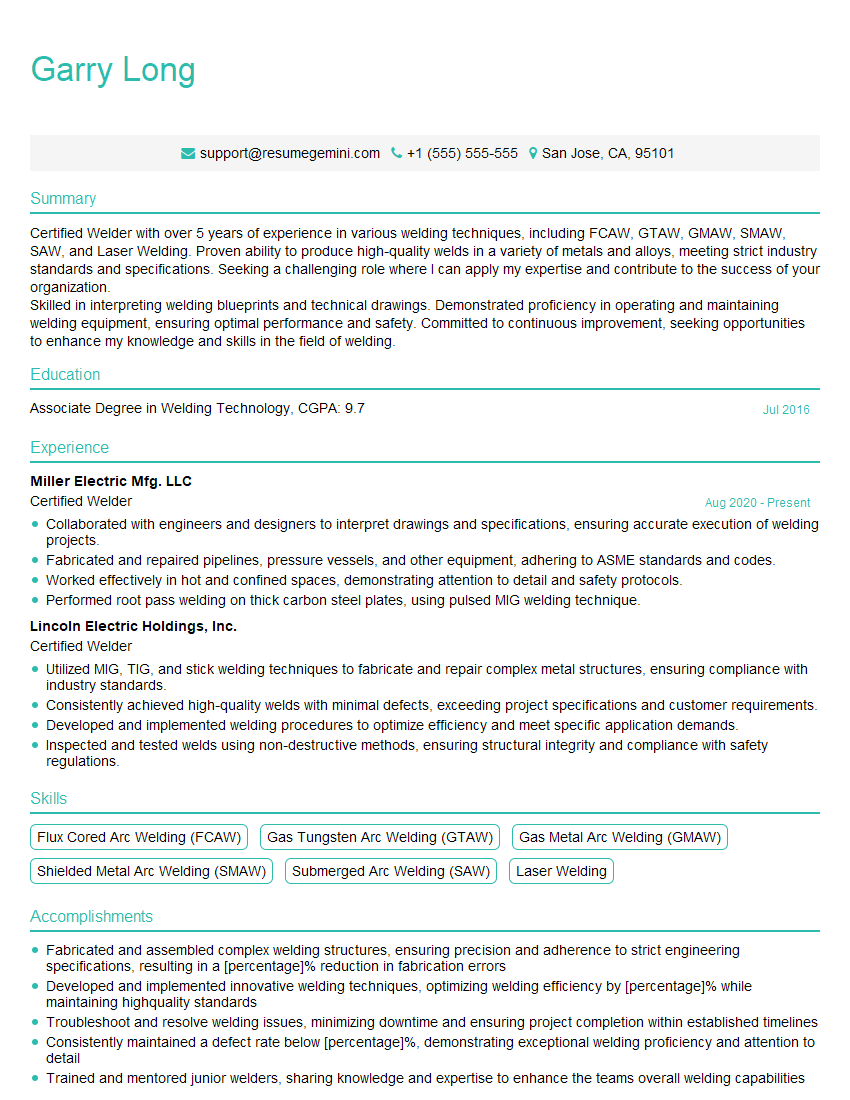

Mastering Welding Machine Operation opens doors to rewarding and diverse career opportunities. To maximize your chances of landing your ideal role, invest time in crafting a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that stands out from the competition. They provide examples of resumes tailored specifically to Welding Machine Operation roles, ensuring your application showcases your capabilities in the best possible light. Take the next step towards your successful career in welding today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO