Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Welding Symbols interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Welding Symbols Interview

Q 1. Explain the purpose and significance of welding symbols.

Welding symbols are a standardized graphical language used in engineering drawings to communicate precise instructions about welds to fabricators. They’re crucial because they eliminate ambiguity and ensure everyone – from the designer to the welder – understands exactly what type of weld is needed, where it should be placed, its dimensions, and any special requirements. Think of them as a universal translation tool for welding instructions, preventing costly mistakes and ensuring consistent, high-quality welds.

Their significance lies in their ability to convey complex welding details concisely. A single symbol can replace pages of written descriptions, reducing errors and saving time. This efficiency is vital in large-scale projects where misinterpretations can have serious consequences.

Q 2. Describe the different types of welding processes represented in welding symbols.

Welding symbols encompass a wide range of welding processes. The symbol itself doesn’t directly *show* the process, but a reference number or letter is used to specify it in a separate legend. Common processes include:

- Gas Metal Arc Welding (GMAW): Often referred to as MIG welding, using a consumable electrode.

- Gas Tungsten Arc Welding (GTAW): Known as TIG welding, using a non-consumable tungsten electrode.

- Shielded Metal Arc Welding (SMAW): Commonly called stick welding, using a consumable electrode with a flux coating.

- Submerged Arc Welding (SAW): A high-deposition process using a consumable electrode submerged in a granular flux.

- Resistance Welding (RW): Using electric current to heat and fuse the metals, like spot welding or seam welding.

The specific process is critical for achieving desired weld properties, and the symbol system ensures this information is clearly communicated.

Q 3. Interpret a welding symbol showing a fillet weld, including size, length, and location.

Let’s say we have a welding symbol with a short vertical line (representing a fillet weld) on the arrow side of the reference line. A dimension ‘6 mm’ is placed above the symbol, and a length dimension ’50 mm’ is placed beside it. This indicates a 6 mm fillet weld, 50 mm long, located on the member indicated by the arrow.

For example, if the arrow points to a vertical plate, then a 6mm fillet weld, 50mm in length, will be applied along the edge of that plate. If further details are included (on the other side of the reference line), additional welds on the other piece being joined would be specified.

Example: 6 mm |----50 mm---- (on arrow side of reference line)The location and dimensions are crucial for the welder to execute the weld accurately. A missing dimension or an unclear location could result in a weld failure or a part that doesn’t meet the specifications.

Q 4. Explain the significance of the reference line in a welding symbol.

The reference line is the foundation of a welding symbol. It’s the horizontal line from which all other elements are referenced. It acts as the baseline for the positioning of the weld relative to the parts being joined. Think of it as a central axis around which the welding instructions revolve.

Everything drawn above or below the reference line indicates characteristics of the weld on the component indicated by the arrow, or on the opposite component. The reference line itself is not a physical part of the weld but rather an organizational element that is essential for correct interpretation.

Q 5. How do you interpret the arrow and its relationship to the weld?

The arrow in a welding symbol points to the component where the weld is to be applied. It’s like an indicator showing the welder ‘This is where you need to weld’. The arrow always points toward the part to be welded and never away from it.

The arrow’s orientation is critical; it defines the side of the joint where the specified weld is to be made. The arrow’s position in relation to the reference line dictates whether the symbol applies to the part the arrow points to (arrow side) or the opposite part.

Q 6. Explain the meaning of different tail symbols (e.g., field weld, groove weld).

Tail symbols placed at the end of the arrow indicate additional welding requirements. They provide supplementary information not conveyed by the main symbol. Some common tail symbols are:

- Field Weld: This symbol indicates that the weld is to be made in the field, typically after the component is in its final position, as opposed to being welded in the factory.

- Groove Weld: This symbol will show the configuration of a groove weld; the shape of the groove is often shown in a supplementary diagram.

- Other Symbols: Symbols may indicate weld all around a circumference, specify a particular type of weld preparation, or indicate a specific welding process (as previously described)

These tail symbols provide crucial information, ensuring that the welder is aware of the specific circumstances and requirements of the weld. Ignoring these symbols could lead to improper execution or even safety hazards.

Q 7. Describe how you would interpret a symbol indicating a specific weld type (e.g., butt weld, lap weld).

The type of weld is often indicated either by the basic symbol used (such as a vertical line for a fillet weld or a symbol for a groove weld) or by a supplementary diagram. For instance, a symbol showing a continuous line could represent a butt weld. For a lap weld, a slightly different symbol would depict how the two pieces overlap.

Interpreting the symbol correctly hinges on understanding the geometric representation of the symbol; a simple line for a fillet weld, a ‘U’ shape for a groove weld, etc. Detailed drawings and legends clarify ambiguities, but the basic shapes are designed to be instantly recognizable.

For example, a butt weld would be shown by a symbol that looks like a simple line drawn between the two parts, whereas a lap weld will show two overlapping parts with the weld bead indicated in the overlap. This allows for quick and accurate interpretation of the welding requirements.

Q 8. How are dimensions and tolerances indicated in welding symbols?

Dimensions and tolerances in welding symbols are crucial for ensuring the weld meets the required specifications. They’re indicated using a combination of numerical values and symbols placed strategically within the welding symbol. The location of these dimensions is key; they often appear near the arrow side (or reference line) to describe the weld’s size, and on the other side of the symbol to describe other dimensions like leg length, throat depth, or the size of a fillet weld.

For example, a dimension of 6 mm near the arrow might indicate the weld’s size, while 4 mm on the other side might refer to the leg length of a fillet weld. Tolerances, which define acceptable variations from the specified dimensions, are usually indicated separately, often using plus/minus notation (e.g., 6 mm ± 1 mm). The standard used (like AWS D1.1) will provide specific guidelines on acceptable tolerance ranges. These can be extremely important for ensuring proper fit and function.

Think of it like a recipe: the dimensions are the precise ingredient measurements, and tolerances are the allowable variations to still get a delicious (functional) weld. Without accurate dimensions and tolerances, you risk creating welds that are too weak or too strong, ultimately impacting structural integrity.

Q 9. Explain the use of supplementary symbols (e.g., weld all around).

Supplementary symbols are like add-ons to the core welding symbol, adding further instructions on how the weld should be executed. The ‘weld all around’ symbol, represented by a continuous circle around the reference line, is a prime example. This symbol clearly instructs the welder to apply the specified weld around the entire joint perimeter.

Other supplementary symbols might indicate details like field welds (welds completed on-site rather than in a factory), the use of backing, the need for specific weld finishes, or the requirement for a particular weld type across the whole joint. Each symbol is carefully defined in relevant welding codes, adding precision to the welding instructions.

Consider a large circular pipe joint. Without the ‘weld all around’ symbol, the welder might only weld a section, leading to a serious structural compromise. This small symbol significantly reduces ambiguity and prevents costly errors.

Q 10. Interpret a welding symbol showing a combination of weld types.

Interpreting a welding symbol showcasing a combination of weld types requires a systematic approach. Each element within the symbol—the basic weld symbol, supplementary symbols, and dimensional information—provides a piece of the puzzle. Let’s say a symbol shows a fillet weld symbol (the triangle) combined with a groove weld symbol (the square). The location of these symbols (on the arrow or opposite side) and the dimensions associated with them will define which weld type is used for which portion of the joint.

For instance, if the fillet weld is on the arrow side and the groove weld symbol is on the other side, and both include dimensions, it implies a fillet weld along one portion of the joint and a groove weld for the remaining section. A clear understanding of the different weld types and their respective symbols is crucial. This approach extends to any combination of weld types represented. Reading the specifications from the drawing as a whole is crucial for a good interpretation.

Imagine a T-joint. Part of it may use a fillet weld for a quick, simple connection, while another section, requiring greater strength, uses a groove weld. The combined symbol precisely communicates this requirement to the welder.

Q 11. Describe how welding symbols indicate the type of weld preparation (e.g., bevel, J-groove).

Weld preparation, which refers to shaping the joint edges before welding, is communicated via specific symbols within the welding symbol. The symbol shows the joint configuration, for example a single bevel, double bevel, V-groove, U-groove, J-groove, or other preparations. These symbols are usually depicted on the basic weld symbol or near it, showing the angle, dimensions of the bevel, depth of the groove, and root opening. Dimensions such as bevel angle, root opening, and depth are crucial for proper penetration and weld quality.

For instance, a double-bevel symbol would show two angles, one on each side of the joint. A ‘V’ groove would show a ‘V’ shape indicating the groove in the joint. These configurations are essential for ensuring the weld filler material correctly fuses with the base metal. Improper preparation leads to defects like lack of fusion or incomplete penetration which seriously weakens the weld.

Think of it like preparing wood for joinery. Different types of joints (like mortise and tenon) require specific cuts to fit properly. Welding preparation symbols provide a similar blueprint for a successful weld.

Q 12. Explain the meaning of symbols representing weld finishing (e.g., grinding, chipping).

Symbols indicating weld finishing specify how the weld should be post-processed to achieve the desired surface finish and quality. Common symbols represent grinding, chipping, or other methods to remove excess weld metal, slag, or spatter. The location of these symbols is crucial; usually they’re placed on the arrow side or opposite side, referring to which side of the weld requires the finishing process.

For instance, a grinding symbol would indicate that the weld surface needs to be ground smooth to achieve a particular surface roughness. A chipping symbol would indicate that excess material should be removed using a chipping hammer. These finishes influence aspects like aesthetics, corrosion resistance, and structural integrity in some applications.

Imagine a weld on a visible part of a ship’s hull. Grinding the weld would ensure a smooth, corrosion-resistant finish, vital for both appearance and durability. These symbols ensure the final product meets high standards for both function and appearance.

Q 13. How do you interpret symbols related to weld testing and inspection?

Symbols related to weld testing and inspection are crucial for ensuring the quality and reliability of the weld. These symbols often appear near the welding symbol and might denote the type of test required (e.g., radiographic testing, ultrasonic testing, visual inspection, mechanical testing etc.). They might also specify the sampling frequency or the acceptance criteria for the weld. These symbols ensure that the weld meets required quality and safety standards.

A common example is a symbol indicating radiographic testing (RT) which requires taking an X-ray of the weld to detect internal defects. Others might indicate the use of mechanical testing (like tensile tests or bend tests) to determine the weld’s strength. These symbols allow for a clear specification of quality control measures. Such clear communication helps prevent catastrophic failures.

For high-consequence welds like those found in bridges or pressure vessels, rigorous testing is vital. The symbols associated with these tests ensure that the weld has undergone the necessary scrutiny to ensure safety and structural integrity.

Q 14. What are some common errors encountered when interpreting welding symbols?

Common errors in interpreting welding symbols often stem from a lack of understanding of the specific standards being followed (like ASME or AWS standards), misinterpreting symbol placement and dimensions, or overlooking supplementary symbols.

For example, mistaking a fillet weld symbol for a groove weld symbol, or misinterpreting the location of a dimension (leading to incorrect weld size), are common errors. Failing to notice a supplementary symbol indicating a particular weld finish or testing requirement can also lead to costly mistakes. A lack of familiarity with the different types of weld joints, weld preparation styles and their associated symbols can also lead to errors. Furthermore, assuming a standard without referencing it can lead to incorrect interpretation.

A methodical and thorough approach is essential—reference the relevant standard, carefully examine each element of the symbol, and never hesitate to clarify any ambiguity with the design engineer. Overlooking a detail can easily lead to a weld that is either substandard or entirely unsuitable for its purpose. Always double-check your interpretation.

Q 15. How do you ensure consistent interpretation of welding symbols in a team?

Consistent interpretation of welding symbols across a team is paramount for safety and project success. Think of it like a shared language; everyone needs to understand the same dialect to avoid miscommunication. We achieve this through a multi-pronged approach.

- Training and Certification: All welders and inspectors undergo rigorous training on the latest AWS standards and symbol interpretation. This includes hands-on practice and regular refresher courses.

- Standardized Documentation: We use a single, approved reference document that outlines all relevant welding symbols and their interpretations, ensuring everyone consults the same source. This could be an internal company standard or a widely accepted code like AWS D1.1.

- Regular Audits and Reviews: We conduct regular audits of welding procedures and drawings to verify correct interpretation and application. These reviews involve cross-checking the symbols against the actual weld execution and identify any inconsistencies early on.

- Communication and Collaboration: Open communication is vital. We encourage welders, inspectors, and engineers to communicate openly if there’s any ambiguity about a symbol. Regular team meetings and collaborative reviews help identify and resolve any misunderstandings proactively.

For instance, in a recent project, a minor discrepancy in the interpretation of a fillet weld symbol was caught during a routine review, preventing a potentially costly rework. This highlights the importance of consistent and thorough training and a culture of collaboration.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do welding symbols relate to relevant welding codes and standards (e.g., AWS D1.1)?

Welding symbols are intrinsically linked to welding codes and standards like AWS D1.1 (Structural Welding Code – Steel) or ASME B31.1 (Power Piping). These codes provide the rules and requirements for welding processes, materials, and quality control. The symbols themselves are a visual shorthand for specifying the weld’s location, type, size, and other crucial parameters.

Think of the code as the rulebook and the symbol as a concise instruction drawn from that rulebook. A welding symbol on a drawing references specific clauses within the code. For example, a particular symbol might indicate a specific weld type that meets the requirements outlined in section 3.5 of AWS D1.1. Without the code, the symbol is meaningless; without the symbol, the code’s application is cumbersome and prone to error.

Therefore, any welding symbol interpretation must always be considered within the context of the relevant welding code. The code dictates the acceptable welding procedures and quality control measures, and the symbol guides the application of these procedures. A mismatch between the symbol and the code requirements will lead to non-compliance and potential safety issues.

Q 17. What is the difference between a structural welding symbol and a piping welding symbol?

While both structural and piping welding symbols use a similar basic framework, key differences exist due to the distinct needs and applications. The fundamental difference lies in the complexity and the need for detailed specifications.

- Structural Welding Symbols: Primarily focus on the type, size, and location of welds in structural steel elements (beams, columns, etc.). They’re relatively simpler, often specifying basic fillet or groove welds. They’re concerned with structural integrity and the load-bearing capacity of the joint.

- Piping Welding Symbols: Are far more detailed. They need to specify not only the weld type and size but also crucial parameters like the type of pipe, pressure rating, material compatibility, and other factors related to fluid containment. They often involve a broader range of weld configurations to handle different pipe fittings and geometries. The emphasis is on leak-tightness and pressure resistance.

For example, a structural weld symbol might just show a fillet weld with a size, whereas a piping weld symbol for the same type of weld might additionally specify the root opening, the reinforcement size, the type of welding process, and the required pre- and post-weld heat treatment.

Q 18. Explain the concept of ‘contour’ in relation to welding symbols.

The ‘contour’ in a welding symbol refers to the shape of the weld’s cross-section. Imagine taking a cross-section through the weld; the contour defines the form of that cross-section. It’s not about the overall length or location of the weld, but about how the weld material fills the joint.

This is often depicted using various lines and symbols within the welding symbol itself. For example, a concave contour might be represented by a specific symbol indicating the weld profile curves inward. A convex contour would be shown by a symbol indicating an outward curve. A flush contour, implying a flat weld surface, would have a different representation. This is crucial because the contour significantly affects the weld’s strength and performance.

For instance, a concave contour might be preferred in certain situations to avoid stress concentrations, while a convex contour might be used in others to increase weld strength.

Q 19. How do you interpret symbols indicating specific weld sizes and configurations?

Interpreting weld size and configuration symbols requires a systematic approach. The symbols themselves are highly standardized, reducing ambiguity.

Size: Weld size is usually indicated numerically on the symbol (e.g., 6 mm or 1/4 inch). This could represent the leg length for fillet welds or the throat thickness for groove welds. The units are usually specified on the drawing.

Configuration: The weld configuration is represented by the various elements of the symbol itself. For example, the type of weld (fillet, groove, spot, etc.), the location of the weld (on which side of the joint), and additional symbols for details like backing, bevel angles, etc.

For example, a symbol showing a 6 mm fillet weld with a particular arrangement of arrows and symbols indicates the size, type, and location of the weld.

It’s critical to follow the sequence in the welding symbol’s notation, reading it as per the specific code’s conventions to avoid misinterpreting the weld configuration. A single mistake can lead to an unacceptable weld.

Q 20. What is the significance of the ‘size’ and ‘leg length’ indications?

The ‘size’ and ‘leg length’ indications in welding symbols are critical for determining the weld’s strength and mechanical properties. They are not interchangeable and their meaning depends on the weld type.

- Size: For groove welds, ‘size’ usually refers to the throat thickness – the shortest distance from the root of the weld to the opposite side. This dimension dictates the weld’s load-bearing capacity.

- Leg Length: For fillet welds, ‘size’ refers to the leg length – the length of the shorter side of the weld’s isosceles right-angled triangle. This dimension also impacts the weld’s strength.

Both size and leg length are essential dimensions that influence weld strength, fatigue resistance, and overall performance. Incorrect interpretation of these values can lead to structural failures. It’s crucial to understand the type of weld before interpreting the ‘size’ notation; a mistake can lead to a significant difference in the weld’s strength and the integrity of the structure.

Q 21. How are different welding processes indicated within the welding symbol?

Different welding processes are usually indicated within the welding symbol using standard abbreviations or process designations. These are often placed within a small, designated area of the symbol, usually near the reference line. For example:

SMAWfor Shielded Metal Arc Welding (stick welding)GMAWfor Gas Metal Arc Welding (MIG welding)GTAWfor Gas Tungsten Arc Welding (TIG welding)SAWfor Submerged Arc Welding

The specific designation used depends on the relevant welding code and standard. Selecting the wrong welding process can significantly impact the weld’s quality and suitability for the intended application. Therefore, it’s imperative to correctly identify and understand the welding process indicated within the symbol to ensure compliance with the design specifications and safety regulations.

Q 22. What are some common misconceptions about welding symbols?

A common misconception is that welding symbols are overly complex and difficult to understand. While they contain a lot of information, they follow a standardized system. Another misconception is that all aspects of the weld are always explicitly detailed in the symbol; often, defaults and industry standards fill in the gaps. Finally, some believe that a thorough understanding of metallurgy isn’t needed to read welding symbols, when in fact, the chosen weld type is directly related to the materials and intended application.

- Misconception: A single symbol always covers every detail.

- Reality: Welding symbols reference standards and often assume certain parameters if not explicitly shown.

- Misconception: Only welders need to understand welding symbols.

- Reality: Engineers, inspectors, and even material scientists need to interpret them to ensure quality and safety.

Q 23. Explain how to identify and interpret different types of groove welds and their symbols.

Groove welds are used to join two pieces of material edge-to-edge. The symbol shows the preparation of the edges and the type of weld. The type of groove weld is indicated by the shape of the groove symbol, located on the arrow side of the reference line. This shape shows the geometry of the joint before welding.

- Square Groove: A simple square or rectangular shape represents a square groove weld.

- V-Groove: A V-shape indicates a V-groove weld, where the edges are beveled at an angle.

- U-Groove: A U-shape depicts a U-groove weld, which features a deeper and wider bevel than a V-groove.

- Bevel Groove: A single-bevel symbol (one side beveled) or a double-bevel symbol (both sides beveled) is used to illustrate bevel groove welds.

- J-Groove: A J-shape is used for a J-groove weld.

The size and angle of the groove are often specified by dimensions added to the symbol. For example, a V-groove might have dimensions indicating the angle of the bevel and the root opening.

Example: A V-groove symbol might look like a 'V' with dimensions such as '60°' and '2mm' added to indicate the bevel angle and root opening respectively.

Q 24. Interpret a symbol indicating a specific backing material.

The backing material is indicated by a small symbol typically placed near the weld symbol. This symbol might be a simple letter, or a more descriptive picture or notation. For example, a ‘B’ might indicate a backing strip of the same or similar material, or perhaps a more defined symbol might indicate a ceramic backing. It’s always important to refer to the accompanying documentation or specifications to clarify the exact nature of the backing material when not explicitly labeled.

Example: A symbol showing a small rectangular block next to the weld symbol might denote a backing strip. A note would specify the material (e.g., copper, steel) and dimensions.

Q 25. Explain the meaning and importance of surface finish indications in a welding symbol.

Surface finish indications detail how smooth or rough the weld surface should be after completion. These are crucial for aesthetics, corrosion resistance, and other performance aspects of the welded joint. Common indications include grinding, chipping, or other surface treatments. These specifications are usually found near the tail end of the symbol, often showing symbols like a grinding wheel or a note stating ‘grind to smooth finish’.

Importance: A poor surface finish can lead to stress concentrations, reduce fatigue life, and provide a place for corrosion to begin. The specified surface finish ensures the structural integrity and long-term durability of the weld.

Example: A symbol indicating 'G' could denote grinding. The exact surface roughness might be specified numerically (e.g., Ra value).

Q 26. How do welding symbols relate to the overall manufacturing process?

Welding symbols are essential for effective communication throughout the manufacturing process. They act as a blueprint for the welding operation, providing clear instructions to welders. Engineers use them to specify the type of weld, its location, and the required quality standards. Inspectors use them to verify that the welds meet the design specifications. In short, welding symbols help in planning, execution, inspection and verification, all critical aspects of the manufacturing process.

Practical Example: In a shipbuilding project, detailed welding symbols are essential for producing strong, water-tight joints. They ensure that all welders create consistent, high-quality welds.

Q 27. Describe how you would approach deciphering a complex welding symbol.

Deciphering a complex welding symbol requires a systematic approach. Begin by identifying the reference line; this line indicates the location of the weld on the part. Then, carefully examine the elements on the arrow side (which specifies the weld) and the other side (which specifies the weld on the opposite side of the part if any). This step-by-step approach is helpful:

- Identify the Reference Line: This line is central to understanding the symbol’s location reference.

- Examine the Arrow Side: Analyze the weld symbol (type, size, etc.).

- Check the Other Side of the Reference Line: Determine if the weld is on both sides of the joint, and if the specifications differ.

- Look for Supplementary Symbols and Dimensions: Consider additional markings like surface finish symbols, backing material indicators, or dimensional details.

- Consult Applicable Standards: Refer to any specifications or standards to clarify ambiguous aspects.

Example: A complex symbol might include multiple groove weld types on one or both sides of a joint with different surface finish requirements on each side; a systematic analysis using the above steps is required.

Q 28. Describe your experience using welding symbols in practical applications.

Throughout my career, I've extensively used welding symbols in various projects. For instance, while working on a large-scale pipeline project, we used them to ensure consistent and high-quality welds across hundreds of kilometers of pipe. In another project involving the fabrication of complex pressure vessels, precise welding symbols were crucial for achieving tight tolerances and ensuring structural integrity. I've worked with both simple and complex symbols, often needing to adapt specifications based on material properties and the specific application's requirements. My experience spans various industries including energy, manufacturing and construction which highlights the ubiquitous nature of welding symbols.

A memorable experience involved resolving a discrepancy between the welding symbol and the final weld. It became clear that the initial symbol lacked crucial details; it had inadvertently omitted the specified surface finish required. This mistake was caught during inspection, highlighting the critical role of accuracy in welding symbol creation and interpretation. This experience reinforced the need for meticulous attention to detail and a comprehensive understanding of the entire design, not just the welding symbol alone.

Key Topics to Learn for Welding Symbols Interview

- Basic Welding Symbol Elements: Understand the reference line, arrow, and their significance in interpreting weld specifications. Practice identifying each component and its meaning.

- Weld Joint Types: Master the different types of weld joints (e.g., butt, lap, tee, corner) and their appropriate welding symbols. Be prepared to discuss the strengths and weaknesses of each joint type and their applications.

- Weld Dimensions and Specifications: Learn how to interpret symbols indicating weld size, length, spacing, and other crucial dimensions. Practice reading and interpreting complex symbol combinations.

- Types of Welds: Familiarize yourself with various weld types (e.g., fillet, groove, plug, slot) and their corresponding symbols. Understand the implications of choosing one type of weld over another for a specific application.

- Welding Processes: While not strictly part of the symbol itself, understanding the different welding processes (e.g., SMAW, GMAW, GTAW) and their relevance to symbol interpretation is crucial. Be ready to discuss how process selection influences symbol design.

- Contour and Surface Symbols: Learn to interpret symbols that indicate the shape and finish of the weld (e.g., concave, convex, flush). This shows attention to detail important in welding.

- Practical Problem Solving: Practice interpreting complex welding symbols and translating them into practical instructions for weld preparation and execution. Be prepared to discuss challenges you might face during interpretation and how you would overcome them.

- Code and Standard Compliance: Understand the importance of adhering to relevant welding codes and standards (e.g., AWS D1.1) when interpreting and applying welding symbols. Discuss your knowledge of relevant safety protocols.

Next Steps

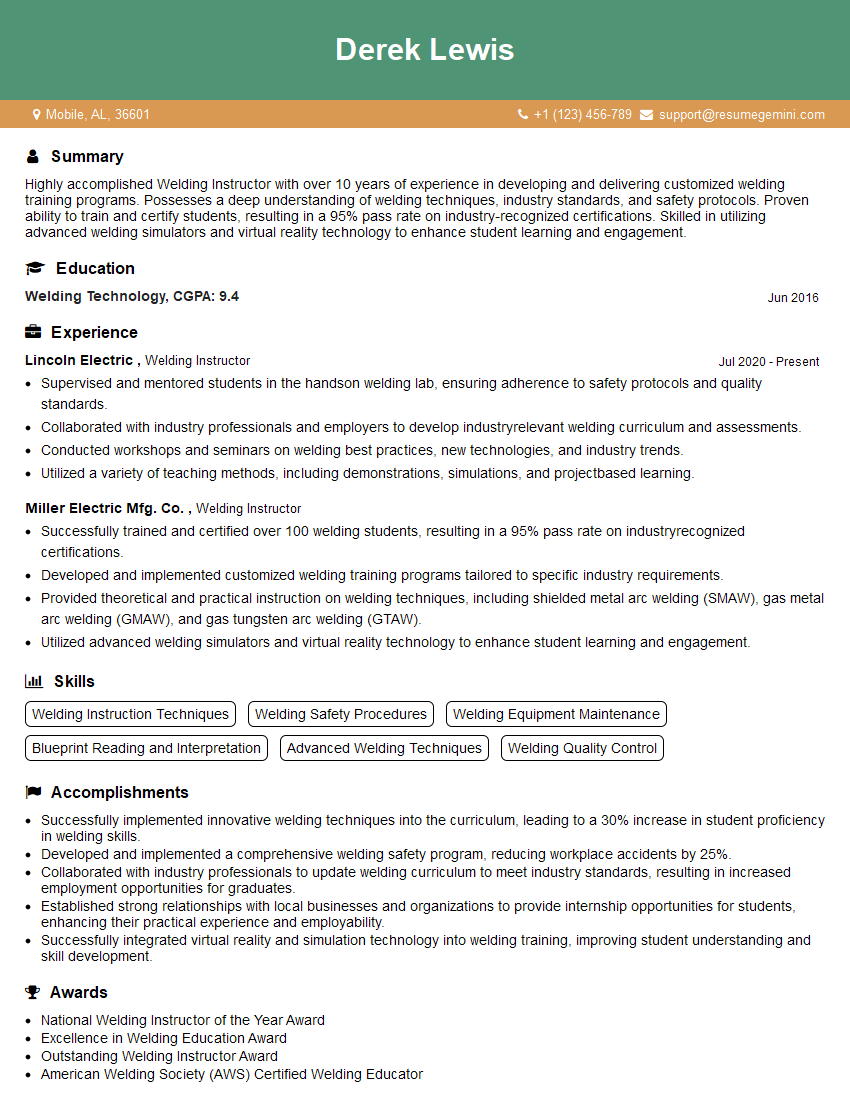

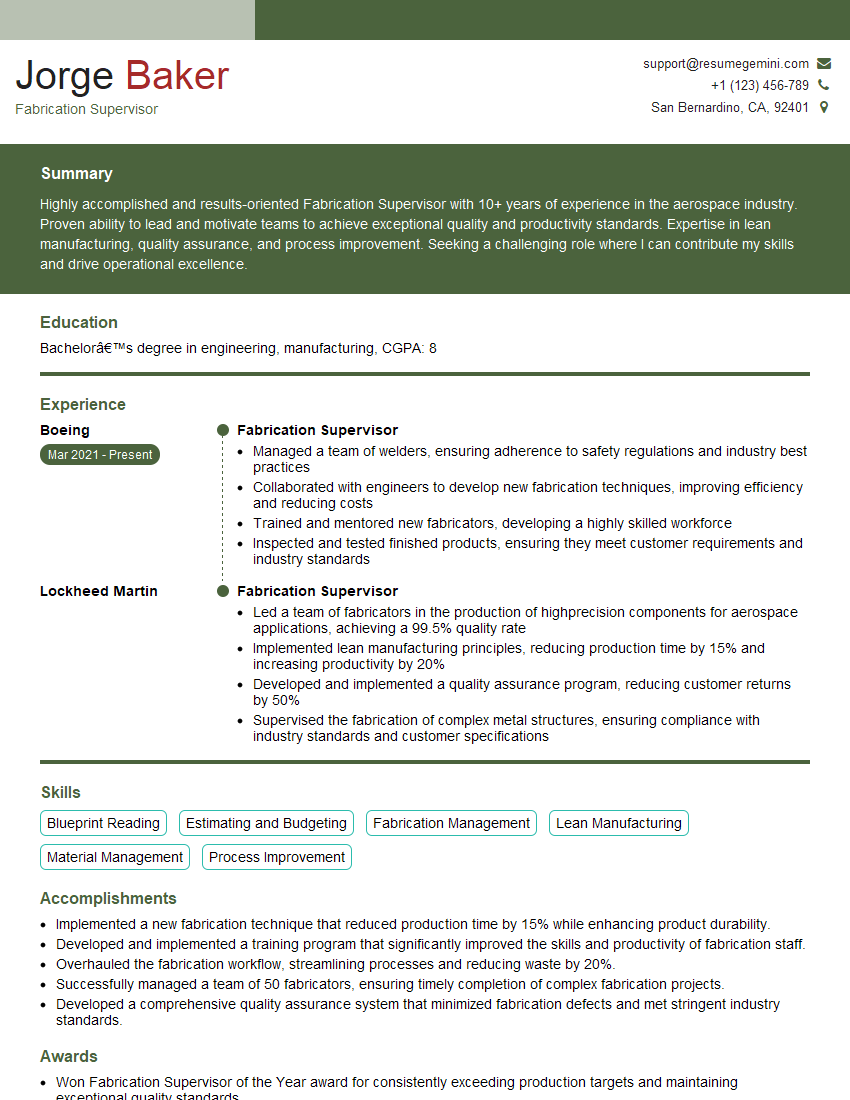

Mastering welding symbols is vital for career advancement in the welding industry. A strong understanding of these symbols demonstrates technical proficiency and attention to detail, opening doors to more challenging and rewarding roles. To maximize your job search success, creating an ATS-friendly resume is crucial. ResumeGemini can help you build a professional and effective resume that highlights your skills and experience. We provide examples of resumes tailored to showcase Welding Symbols expertise, helping you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO