Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Wheel and Axle Repair interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Wheel and Axle Repair Interview

Q 1. Describe your experience diagnosing wheel bearing failures.

Diagnosing wheel bearing failures involves a systematic approach combining visual inspection, sound analysis, and sometimes, road testing. A failing wheel bearing often manifests as a growling or humming noise that increases with speed. This noise is usually more pronounced when turning. Visually, I’d look for signs of grease leakage, play (movement) in the wheel hub, or unusual wear on the tire tread. For example, uneven wear could indicate a binding bearing. If there’s play in the wheel, I’d use a pry bar to check the degree of movement – excessive play is a clear indication of a faulty bearing. Finally, a road test can confirm my suspicions; a noticeable vibration or pull to one side while driving strongly suggests a bearing problem. I would always compare the suspect wheel to its counterpart for comparison.

Q 2. Explain the process of aligning wheels and axles.

Wheel and axle alignment is crucial for safe and efficient vehicle operation. The process generally involves using specialized equipment like a wheel alignment machine. This machine measures the angles of the wheels relative to each other and to the vehicle’s chassis – parameters like camber, caster, and toe. The procedure starts with a thorough inspection to identify any damage or worn components that might affect the alignment. Then, the machine precisely measures the current alignment angles. Based on these measurements and manufacturer specifications, adjustments are made to the suspension components (tie rods, control arms, etc.) to bring the angles within the acceptable range. After adjustments, the machine verifies that the alignment is accurate. Improper alignment can lead to premature tire wear, poor handling, and reduced fuel efficiency; therefore precision is critical.

Q 3. How do you inspect wheel and axle components for wear and tear?

Inspecting wheel and axle components for wear and tear involves a meticulous examination of each part. I’d start by visually inspecting the wheels for cracks, bends, or corrosion. Then, I’d check the tires for uneven wear, which could indicate underlying alignment or suspension issues. The wheel bearings are carefully examined for play, roughness, or noise. Axles are inspected for bending, scoring, or any signs of damage. I’d also check the wheel studs and nuts for wear or damage. Lubrication points, like those for the kingpin (if applicable), are checked. Measuring critical dimensions with calipers might be necessary to ensure components are within tolerances. The entire process documents findings and guides the next steps – repair or replacement.

Q 4. What are the common causes of wheel wobble or vibration?

Wheel wobble or vibration can stem from several sources. Unbalanced wheels are a very common cause. An imbalance creates centrifugal force as the wheel rotates, leading to vibration felt in the steering wheel or the vehicle. Out-of-round wheels or tires, where the diameter isn’t consistent, also cause vibration. Worn wheel bearings, as mentioned previously, can produce a characteristic wobble. Damaged or worn suspension components like ball joints, tie rod ends, or control arm bushings can also contribute. Finally, improper wheel alignment can significantly induce vibration or wobble. Systematic diagnosis, checking each potential source, is key to identifying the root cause. For instance, a simple wheel balance often resolves minor vibrations, whereas suspension component replacement might be needed for more severe issues.

Q 5. Explain the different types of wheel and axle assemblies.

Wheel and axle assemblies vary depending on the vehicle type and application. Some common types include:

- Independent suspension systems: Each wheel is mounted on a separate suspension unit, allowing for independent movement. This is common in passenger cars.

- Live axles: The wheels are mounted on a single axle that rotates as a unit. This setup is often found in trucks and older vehicles. They can be ‘solid’ axles which are rigidly fixed, or ‘floating’ axles where the axle isn’t directly involved in carrying the vehicle’s weight.

- Driven axles: These transfer power from the engine to the wheels. Examples include the rear axle in a rear-wheel-drive vehicle.

- Non-driven axles: These simply support the vehicle and don’t transmit power. The front axle in a rear-wheel-drive vehicle is a good example.

The specific design impacts the maintenance and repair procedures; for example, an independent suspension system might have more individual components to check than a live axle.

Q 6. How do you determine the correct torque specifications for wheel nuts?

Determining the correct torque for wheel nuts is essential for safety. Over-tightening can damage the wheel studs or nuts, while under-tightening can lead to wheel detachment. I always refer to the vehicle’s owner’s manual or a reliable repair manual for the specific torque specifications for the particular vehicle’s wheel nuts. These specifications are usually expressed in Newton-meters (Nm) or foot-pounds (lb-ft). I use a calibrated torque wrench to ensure that the nuts are tightened to the correct value. It’s important to remember that the torque wrench’s calibration should be verified periodically to guarantee accuracy. Inconsistent tightening can lead to uneven wheel stress and affect alignment or balance, impacting safety and tire life.

Q 7. Describe your experience with different types of wheel bearings.

Wheel bearings come in various types, each with its advantages and disadvantages:

- Tapered roller bearings: These are very common in automotive applications. They are durable and can handle high loads and speeds. The tapered design allows for better load distribution.

- Ball bearings: Simpler in construction and often used in lighter-duty applications, they offer smoother operation at lower loads.

- Hub bearings: Often integrated into the wheel hub, they simplify assembly and are easy to replace.

- Sealed bearings: Pre-lubricated and sealed units require minimal maintenance but are more expensive and aren’t serviceable; once the seal is damaged, the whole unit needs replacement.

My experience involves diagnosing issues related to each of these bearing types and choosing the correct replacement bearing for the specific vehicle. Choosing the wrong bearing type can lead to premature wear, noise, and potentially dangerous failure.

Q 8. How do you troubleshoot a malfunctioning wheel brake system?

Troubleshooting a malfunctioning wheel brake system starts with a thorough visual inspection. Look for obvious signs like leaking fluid, worn brake pads, or damaged calipers. Then, we move to a more systematic approach.

- Check brake fluid level: Low fluid indicates a leak somewhere in the system.

- Test pedal feel: A spongy or low pedal indicates air in the lines or a failing master cylinder.

- Inspect brake lines and hoses: Look for any signs of damage, cracks, or leaks.

- Inspect brake calipers and wheel cylinders: Check for leaks, sticking pistons, or damage.

- Check brake rotors and drums: Look for excessive wear, scoring, or warping.

- Test for brake drag: If the wheel is difficult to turn when the brakes are released, there might be binding in the caliper or a seized parking brake.

For example, I once encountered a vehicle with a spongy brake pedal. After a careful inspection, I discovered a small leak in a brake hose. Replacing the hose restored the braking system to full functionality. We always use a pressure bleeder to ensure proper bleeding after repairs to remove any air from the brake lines.

Q 9. What safety procedures do you follow when working with heavy vehicle wheels and axles?

Safety is paramount when working with heavy vehicle wheels and axles. We always follow these procedures:

- Secure the vehicle: Use wheel chocks and engage the parking brake to prevent accidental movement.

- Use proper lifting equipment: Employ a jack rated for the vehicle’s weight and use jack stands for added safety.

- Wear appropriate Personal Protective Equipment (PPE): This includes safety glasses, gloves, and steel-toed boots.

- Follow lockout/tagout procedures: If working near any electrical or hydraulic systems, ensure they are properly de-energized and locked out.

- Use torque wrench for tightening: Improper tightening can lead to damage or failure. The correct torque values are always consulted from the vehicle’s service manual.

- Never work under a vehicle supported only by a jack. Always use jack stands.

One time, a colleague failed to properly secure a vehicle during a wheel change, resulting in a minor accident. That reinforced the importance of consistent adherence to safety protocols.

Q 10. How do you identify and repair damaged wheel rims?

Identifying and repairing damaged wheel rims requires careful examination. We check for:

- Bends or cracks: These can be visually identified or checked with a straight edge.

- Curb rash: Minor cosmetic damage that often doesn’t affect structural integrity.

- Corrosion: Extensive corrosion can weaken the rim and lead to failure.

- Leaks: Air leaks can be detected using soapy water.

Minor bends might be repairable through careful straightening using specialized tools. However, cracks or severe bends usually necessitate replacement. For corrosion, cleaning and possibly repainting might suffice, depending on the severity. We always follow manufacturer’s recommendations for rim repair or replacement.

Q 11. Explain the process of replacing a damaged wheel stud or bolt.

Replacing a damaged wheel stud or bolt is a straightforward but critical procedure. We follow these steps:

- Remove the wheel: Using a wheel wrench, carefully remove the affected wheel.

- Remove the damaged stud or bolt: This may require the use of penetrating oil and specialized tools, such as a stud extractor, depending on the condition of the stud/bolt.

- Clean the threads: Ensure the threads in the wheel hub are clean and free from debris.

- Install the new stud or bolt: Hand-tighten the new stud or bolt before tightening it to the manufacturer’s specified torque using a torque wrench.

- Reinstall the wheel: Ensure that the wheel is properly seated and tightened to the correct torque.

It’s crucial to use the correct replacement part, as using the wrong size can lead to serious safety issues. Always use a torque wrench to ensure the wheel nuts are tightened to the manufacturer’s specifications.

Q 12. Describe your experience with wheel balancing techniques.

Wheel balancing is essential for smooth vehicle handling and tire longevity. I have extensive experience with both static and dynamic balancing techniques. Static balancing involves balancing the wheel on a single plane, while dynamic balancing accounts for the wheel’s rotation and identifies imbalances in multiple planes.

We use a computerized wheel balancer to accurately identify the location and amount of weight needed for balance. This machine measures the imbalances in the wheel and provides precise locations for the addition of weights. These weights are then carefully attached to the wheel rim to counteract the imbalances. I ensure that the wheel is perfectly balanced after each service. An unbalanced wheel can lead to vibrations, premature tire wear and damage to suspension components.

Q 13. How do you address issues related to wheel alignment?

Addressing wheel alignment issues involves adjusting the angles of the wheels to optimize tire contact with the road surface. This includes adjusting caster, camber, and toe. Improper alignment leads to uneven tire wear, poor handling, and reduced fuel efficiency.

We use specialized alignment equipment to measure the current angles and make adjustments to the steering linkage and suspension components. The process typically involves several adjustments and precise measurements to achieve optimal alignment. After the adjustment, a final check and printout are usually given to the customer as a report. Proper alignment ensures the vehicle drives smoothly and safely.

Q 14. How do you determine if an axle needs to be replaced or repaired?

Determining whether an axle needs repair or replacement depends on the extent of the damage. We carefully inspect the axle for:

- Bends or cracks: These compromises the structural integrity of the axle.

- Wear and tear: Excessive wear can weaken the axle, but sometimes repair is possible through machining or rebuilding.

- Corrosion: Severe corrosion can necessitate replacement.

- Damage from accidents: Significant impact damage often requires replacement.

For minor bends or wear, repair might be feasible. However, cracks, severe corrosion, or significant impact damage usually necessitate replacement to maintain safety. The final decision is made after careful evaluation and adherence to manufacturer’s specifications and safety guidelines. A faulty axle can cause catastrophic failure, so safety is paramount.

Q 15. What tools and equipment are commonly used in wheel and axle repair?

Wheel and axle repair requires a diverse set of tools and equipment, ranging from basic hand tools to specialized machinery. The specific tools needed depend on the nature of the repair, but common items include:

- Jacks and Stands: Essential for safely lifting and supporting the vehicle during repairs.

- Wheel Chocks: Crucial for safety, preventing accidental movement.

- Impact Wrench: Used for quickly and efficiently removing and installing wheel nuts.

- Torque Wrench: Precisely tightens wheel nuts to the manufacturer’s specifications, preventing damage and ensuring safety.

- Wheel Bearing Pullers and Installers: Specialized tools for removing and installing wheel bearings.

- Axle Stands: Provide secure support for the axle during repairs.

- Various Wrenches and Sockets: For removing and installing bolts and nuts on various components.

- Measuring Tools: Calipers, rulers, and dial indicators are used for precise measurements during repairs and inspections.

- Welding Equipment (if applicable): For repairing damaged axle components, including MIG and TIG welders, along with appropriate safety equipment.

- Lubrication Equipment: Grease guns and oil cans are necessary for applying lubricants to bearings and other moving parts.

Think of it like a well-stocked toolbox for a mechanic specializing in the locomotion system of a vehicle. Each tool has its specific purpose, contributing to the overall efficiency and safety of the repair process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience using diagnostic tools to identify wheel and axle problems.

Diagnostic tools play a crucial role in identifying wheel and axle problems efficiently. My experience includes using a range of diagnostic techniques, from visual inspections to sophisticated equipment. Visual inspection often reveals obvious damage like cracks, bends, or excessive wear. Beyond visual inspection, I use:

- Vibration Analyzers: These tools detect imbalances and vibrations indicating bearing wear, axle shaft damage, or wheel unbalance. For example, a high-frequency vibration might point to a failing wheel bearing.

- Runout Gauges: These precisely measure the runout of the wheel and axle assembly, identifying any inconsistencies that could lead to premature wear or safety issues. A significant runout indicates a potential problem with alignment or component damage.

- Bearing Inspection Tools: Specialized tools that assess the condition of wheel bearings by checking for play and noise.

- Digital Torque Wrenches: These provide accurate readings, ensuring proper tightening and preventing premature component wear.

Recently, I diagnosed a recurring vibration in a vehicle using a vibration analyzer. The analysis pinpointed a specific frequency, leading us to replace a worn-out wheel bearing. This precise diagnosis avoided unnecessary repairs and ensured the safety of the vehicle.

Q 17. How do you ensure proper lubrication of wheel and axle components?

Proper lubrication is paramount for the longevity and performance of wheel and axle components. Insufficient lubrication leads to increased friction, heat, premature wear, and potential catastrophic failure. My approach to lubrication follows these steps:

- Identify Lubrication Points: Precisely locate all lubrication points, including wheel bearings, axle splines, and other moving parts.

- Select Appropriate Lubricant: Use the correct type and grade of lubricant as specified by the vehicle manufacturer. This often involves using specialized high-temperature greases for wheel bearings.

- Clean the Area: Thoroughly clean the area around the lubrication points to remove dirt, debris, and old grease. Contamination can significantly reduce the effectiveness of new lubricant.

- Apply Lubricant: Apply the lubricant using a grease gun for bearings or an oil can for other components, ensuring complete coverage and proper penetration.

- Check for Leaks: After application, inspect for any lubricant leaks. Leaks indicate potential seal damage or other issues needing further attention.

Imagine your wheel bearings as gears in a clock; proper lubrication keeps them turning smoothly. Ignoring this crucial step is like letting the clock run dry—it’ll eventually stop working.

Q 18. What are the common causes of axle shaft damage?

Axle shaft damage can stem from a variety of causes, often resulting in significant vehicle safety issues. Common causes include:

- Excessive Load: Overloading the vehicle beyond its weight capacity can stress the axle shafts, leading to bending, cracking, or even complete failure.

- Impact Damage: Collisions or severe potholes can inflict significant damage to axle shafts, causing bending or fracturing.

- Corrosion: Rust and corrosion weaken the axle shaft material, making it susceptible to failure. Exposure to road salt is a significant contributor to corrosion.

- Fatigue: Repeated stress on the axle shaft, particularly during harsh driving conditions, can lead to metal fatigue and eventual fracture. This is often seen as a gradual weakening over time.

- Improper Installation or Maintenance: Incorrect installation of components or neglect of lubrication can accelerate wear and tear, ultimately damaging the axle shaft.

Think of it like bending a paperclip repeatedly; eventually, it will break. Similarly, repeated stress on an axle shaft will eventually lead to failure if not addressed properly.

Q 19. Describe your experience with welding repairs on wheel and axle components.

Welding repairs on wheel and axle components require significant skill and precision, adhering strictly to safety protocols. I have extensive experience in welding repairs, focusing on maintaining the integrity of the repaired component. My approach includes:

- Proper Preparation: Thoroughly cleaning and preparing the area to be welded, removing any rust, contaminants, or damaged metal is critical for a strong weld.

- Preheating (if necessary): Depending on the material and thickness, preheating may be necessary to prevent cracking during the welding process.

- Selecting the Right Welding Process: Using the appropriate welding process (MIG, TIG, etc.) and filler material ensures a strong and durable repair. MIG welding is often used for its speed and efficiency, while TIG welding offers more precision for critical repairs.

- Post-Weld Inspection: After welding, a thorough inspection is performed to check for imperfections, ensuring the weld is sound and free from cracks or porosity. This may involve visual inspection and sometimes the use of non-destructive testing techniques.

- Heat Treatment (if necessary): Depending on the material and repair, heat treatment may be required to relieve stress in the welded area and prevent future cracking.

Welding an axle component is akin to surgically repairing a bone; precision, care, and proper technique are essential for a successful outcome and maintaining the structural integrity of the repaired part.

Q 20. How do you handle situations where wheel or axle components are damaged beyond repair?

When wheel or axle components are damaged beyond economical repair, replacement is the only safe and viable option. This decision involves several factors, including the extent of damage, the cost of repair versus replacement, and the safety implications. My procedure involves:

- Thorough Assessment: Conducting a comprehensive assessment to determine the extent of the damage. Sometimes, seemingly minor damage can indicate deeper underlying problems.

- Parts Sourcing: Identifying and sourcing replacement parts from reputable suppliers, ensuring they meet the required specifications and quality standards.

- Installation: Properly installing the replacement parts, following manufacturer’s recommendations and adhering to strict safety protocols.

- Post-Repair Inspection: After the replacement, conducting a thorough inspection to ensure proper functionality and alignment of all components.

- Documentation: Maintaining accurate records of the repair, including the parts used, the repair process, and any relevant measurements.

Replacing a damaged component is like replacing a worn-out tire—it’s a necessary step for maintaining the overall safety and reliability of the vehicle. Ignoring this can lead to potential hazards down the road.

Q 21. Explain the importance of proper wheel torque and its effects on vehicle safety.

Proper wheel torque is critical for vehicle safety and handling. It refers to the rotational force applied to tighten the wheel nuts, ensuring the wheel is securely attached to the vehicle. Incorrect torque can lead to:

- Wheel detachment: Under-tightening can cause the wheel to detach from the vehicle while driving, leading to a loss of control and potentially a serious accident.

- Wheel damage: Over-tightening can damage the wheel studs, nuts, or even the wheel itself. This can cause the wheel to become misaligned, leading to vibrations and premature wear.

- Brake system issues: Incorrect torque can also affect the braking system, resulting in reduced braking efficiency and increased stopping distances.

Imagine your wheels as the feet of your car; they need to be firmly attached to the ground for proper and safe movement. Improper torque jeopardizes this essential connection, compromising safety.

Always use a calibrated torque wrench to ensure the wheel nuts are tightened to the manufacturer’s specified torque values. These values are usually found in the vehicle’s owner’s manual or online databases. Failure to adhere to these guidelines can have dire consequences.

Q 22. How do you maintain accurate records of wheel and axle repairs and maintenance?

Maintaining accurate records is paramount in wheel and axle repair. It’s not just about compliance; it’s about ensuring the safety and longevity of the vehicle. We use a combination of digital and physical methods.

- Digital Database: We utilize a comprehensive software system to meticulously track each repair. This includes the vehicle identification number (VIN), date of service, specific repairs performed (e.g., wheel bearing replacement, axle alignment), parts used (with serial numbers where applicable), technician’s name, and any relevant diagnostic information. This database allows for easy searching, reporting, and analysis of repair history for individual vehicles or across the entire client base.

- Physical Records: We maintain hard copies of work orders, repair invoices, and inspection reports. These serve as a backup and facilitate quick access in case of digital system failure. Photographs of before-and-after repairs are also included for clear documentation.

- Inspection Reports: Each repair begins and ends with a thorough inspection. Detailed reports outlining pre- and post-repair conditions are created, including measurements, observations on wear and tear, and any additional recommendations. These reports often include images as well.

This dual approach ensures data redundancy and allows for efficient retrieval of information, contributing to both operational efficiency and customer satisfaction.

Q 23. Describe your experience working with different types of suspension systems.

My experience encompasses a wide range of suspension systems, from simple leaf spring setups found in older trucks to complex independent suspension systems in modern passenger vehicles.

- Leaf Spring Systems: I’m proficient in identifying and addressing issues like broken leaves, worn bushings, and incorrect spring alignment. For instance, I’ve successfully repaired numerous leaf spring systems in heavy-duty vehicles, requiring careful assessment of load capacity and proper alignment for safe operation.

- Coil Spring Systems: I regularly work with coil spring systems, diagnosing problems such as worn or broken springs, strut failures, and damaged shock absorbers. One memorable case involved identifying a subtle but critical issue with a coil spring’s seating that was causing premature wear on other suspension components.

- Independent Suspension Systems: Modern cars use intricate independent systems (MacPherson struts, multi-link, etc.). Diagnosing issues here demands a deep understanding of geometry and component interaction. I’ve tackled everything from replacing ball joints and control arms to performing complex alignments using state-of-the-art wheel alignment equipment. Understanding the intricacies of electronic suspension systems is also a key part of my expertise.

My approach always involves a systematic diagnostic process, using both visual inspection and advanced diagnostic tools to accurately pinpoint the problem before initiating repairs.

Q 24. How do you address customer concerns regarding wheel and axle issues?

Addressing customer concerns requires empathy, clear communication, and technical expertise. I always start by actively listening to the customer’s description of the problem.

- Active Listening: I try to understand their concerns without interrupting, ensuring I fully grasp the nature and severity of the issue.

- Thorough Inspection: A detailed inspection of the vehicle is then conducted, using diagnostic tools as necessary. This allows me to verify the customer’s concerns and provide an accurate diagnosis.

- Clear Explanation: I explain the findings in plain language, avoiding technical jargon, and providing visual aids where appropriate (e.g., showing them the damaged part).

- Options and Costs: I lay out various repair options, clearly explaining the costs and benefits of each approach, including the potential consequences of delaying repairs.

- Realistic Expectations: I manage expectations by providing realistic timelines for repairs and keeping the customer updated on progress.

By building trust through transparency and clear communication, I aim to leave customers feeling informed, confident, and satisfied with the service received.

Q 25. Explain your understanding of relevant safety regulations pertaining to wheel and axle repair.

Safety is paramount in wheel and axle repair. My understanding of relevant regulations is comprehensive and always kept current.

- DOT Regulations: I’m well-versed in Department of Transportation (DOT) regulations concerning wheel and axle components, including tire pressure, wheel bearing tolerances, axle load limits, and brake system integrity. These regulations vary based on vehicle type and application (commercial versus passenger). Non-compliance can lead to serious safety risks and legal ramifications.

- OSHA Standards: I adhere to Occupational Safety and Health Administration (OSHA) standards for safe work practices in the repair shop, encompassing proper handling of heavy components, using appropriate safety equipment (e.g., jack stands, safety glasses, gloves), and maintaining a clean and organized workspace.

- Local Regulations: I am also aware of and comply with any applicable local regulations and licensing requirements.

Regularly reviewing these guidelines ensures our shop operations remain compliant and safety is consistently prioritized. We conduct regular safety training for all technicians.

Q 26. What are your preferred methods for documenting repair procedures?

My preferred methods for documenting repair procedures prioritize clarity, completeness, and traceability.

- Digital Work Orders: I use a digital work order system that allows for detailed descriptions of the repairs, including part numbers, quantities, and associated labor costs. Digital images of the before and after states are crucial and are integrated into the system.

- Detailed Repair Procedures: Each repair procedure is documented step-by-step, including specific torque specifications, alignment settings, and any other relevant technical details. This ensures consistency and accuracy across all repairs.

- Technician Signatures: The work order includes the technician’s signature, confirming the work’s completion and accuracy of the documentation.

This documented process allows for auditing, facilitates training, and helps resolve any discrepancies that may arise later. These detailed records are essential for warranty claims, and provide a history of the vehicle’s maintenance.

Q 27. How do you stay up to date with the latest technologies and techniques in wheel and axle repair?

Staying current in this field is crucial due to the constant advancements in vehicle technology and repair techniques.

- Professional Organizations: I actively participate in professional organizations, attending conferences, workshops, and webinars to learn about the latest advancements in wheel and axle repair. This includes staying informed on new diagnostic tools and equipment.

- Manufacturer Training: We work closely with manufacturers of wheel and axle components, attending their training sessions to stay updated on their latest products and recommended repair procedures.

- Industry Publications: I read industry publications and journals to keep abreast of the latest research, best practices, and emerging technologies. This includes online forums and technical articles.

- Continuing Education: I actively pursue continuing education opportunities, attending courses and workshops to maintain and enhance my technical skills and knowledge.

Keeping my skills sharp through continuous learning ensures that I can provide my customers with the highest quality of service using the most up-to-date techniques and technologies.

Key Topics to Learn for Wheel and Axle Repair Interview

- Wheel Alignment and Geometry: Understanding camber, caster, and toe angles; diagnosing and correcting misalignment issues; using wheel alignment equipment.

- Axle Inspection and Repair: Identifying damage to axles (bending, cracking, wear); performing visual inspections and using diagnostic tools; understanding different axle types and repair techniques (welding, straightening).

- Bearing and Hub Assembly: Understanding bearing types and their functions; diagnosing bearing failures (noise, play); proper installation and removal procedures; torque specifications.

- Brake System Integration: Relationship between wheel/axle components and the braking system; diagnosing brake issues related to wheels and axles; understanding ABS systems and their impact on wheel and axle repair.

- Suspension System Interaction: How wheel and axle components interact with suspension systems; troubleshooting suspension-related issues that affect wheel and axle performance; understanding different suspension types.

- Wheel Repair Techniques: Understanding different types of wheel damage (bending, cracking); repairing alloy wheels vs. steel wheels; using specialized wheel repair equipment.

- Troubleshooting and Diagnostics: Utilizing diagnostic tools and techniques to identify the root cause of wheel and axle problems; systematic approach to fault finding; documenting repair procedures.

- Safety Procedures and Regulations: Understanding relevant safety regulations and procedures for working with heavy machinery and potentially hazardous materials; proper use of personal protective equipment (PPE).

Next Steps

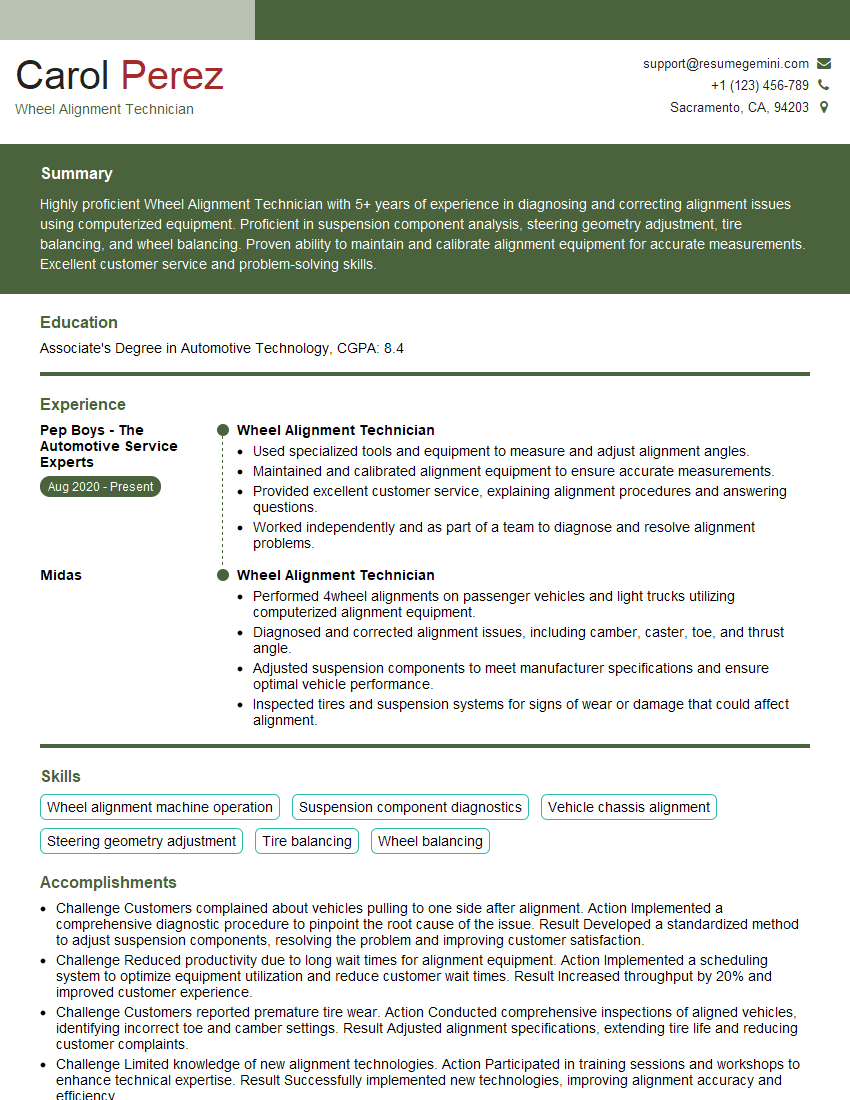

Mastering Wheel and Axle Repair opens doors to a rewarding career with excellent growth potential. This specialized skillset is highly sought after in the automotive and transportation industries, leading to increased earning potential and career advancement opportunities. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is essential for getting your application noticed by employers. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored to Wheel and Axle Repair to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO