Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Xerographic Copier Operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Xerographic Copier Operation Interview

Q 1. Explain the xerographic process step-by-step.

The xerographic process, also known as dry copying, is a fascinating multi-step procedure that creates copies using electrostatic charges. Think of it like a sophisticated static cling situation, but instead of socks, we’re dealing with toner and paper!

- Charging: A photosensitive drum is given a uniform electrostatic charge. Imagine this drum as a giant magnet attracting tiny toner particles.

- Exposure: The image to be copied is projected onto the drum. Light hitting the drum neutralizes the charge in those areas, leaving a latent electrostatic image. This is like shining a light on a part of the magnet, making it lose its attraction in that specific spot.

- Developing: Toner particles, which are finely powdered pigments with an electrostatic charge, are attracted to the charged areas of the drum, forming a visible toner image. This is where the ‘ink’ sticks to the parts of the magnet that still have an attraction.

- Transferring: A sheet of paper, also electrostatically charged, is brought into contact with the drum. The toner image transfers from the drum to the paper.

- Fusing: The paper with the toner image passes through a fuser unit, which uses heat and pressure to melt and permanently bond the toner to the paper. This is the step where the ‘ink’ gets permanently stuck.

- Cleaning: Any remaining toner on the drum is cleaned off, preparing it for the next cycle. This is essential to ensure a clear image for the next copy.

This entire process happens incredibly quickly, usually within seconds, producing a high-quality copy. Each step is crucial; a malfunction in any part can lead to various printing issues.

Q 2. What are the common causes of toner jams?

Toner jams are a common nuisance in copiers, often stemming from a few key culprits:

- Low-quality toner: Using cheap or incompatible toner can lead to clumping and jamming. Think of it like using the wrong type of glue – it won’t stick properly.

- Worn or damaged toner cartridge: A worn-out cartridge may not feed toner evenly, leading to uneven distribution and jams. An old, brittle cartridge is like a leaky water bottle – the contents don’t stay put.

- Incorrect toner installation: Improperly installed toner cartridges can cause jams. It’s like trying to force a square peg into a round hole.

- High humidity or temperature: Extreme environmental conditions can affect toner flow and cause jams. Think of how heat can make chocolate melt – it can do similar things to toner.

- Mechanical issues: Sometimes, the internal components of the copier, such as the toner hopper or transfer rollers, might be malfunctioning, leading to jams. This requires professional attention.

Regular maintenance, such as checking toner levels and replacing cartridges as needed, can significantly reduce the risk of toner jams.

Q 3. How do you troubleshoot a paper jam?

Troubleshooting a paper jam requires a methodical approach. Safety first! Always turn off the copier before attempting to clear a jam.

- Locate the jam: Most copiers have clear indicators or error messages showing where the jam is located. Follow those instructions carefully.

- Access the jammed paper: Gently remove the jammed paper. Avoid tearing the paper, as this can cause further damage. If the paper is severely jammed, use tweezers or other tools to carefully extract it.

- Check for obstructions: After removing the jammed paper, visually inspect the paper path for any obstructions or debris. Sometimes a small piece of paper or a foreign object can cause a jam.

- Clean the rollers: Clean any rollers or other components that come into contact with the paper. Use a lint-free cloth and a cleaning solution specifically designed for copiers. Dirty rollers can prevent smooth paper flow.

- Test the copier: After resolving the jam, run a test copy to ensure the problem is solved. If the issue persists, further troubleshooting might be necessary.

Remember, persistence and patience are key when dealing with paper jams. If the issue persists after following these steps, it’s always best to contact a service professional.

Q 4. Describe the different types of paper handling issues and their solutions.

Paper handling issues can significantly impact the quality and efficiency of your copier. Here are some common problems and their solutions:

- Paper jams: (See answer to question 3)

- Misfeeds: This occurs when the paper doesn’t feed correctly into the copier. Solutions include ensuring the paper tray is properly loaded, using the correct paper type and weight, and cleaning the paper feed rollers.

- Paper wrinkles or creases: Wrinkled or creased paper can lead to jams or poor print quality. Solutions include using high-quality paper, avoiding excessively humid environments, and properly storing paper.

- Paper tray issues: Incorrectly loaded paper trays or damaged trays can cause misfeeds. Solutions include ensuring that the paper tray is properly seated and free of obstructions, and repairing or replacing a damaged tray.

- Paper curl: Curled paper can cause jams or uneven feeding. Solutions include using paper with low moisture content and avoiding extreme temperatures or humidity.

Addressing these issues ensures smoother operation and less downtime. Proper paper handling is an often-overlooked aspect of maintaining copier health.

Q 5. What are the safety precautions when working with a copier?

Safety is paramount when working with any office equipment, including copiers. Here are essential safety precautions:

- Turn off the copier: Always turn off and unplug the copier before performing any maintenance or repairs. This prevents electric shocks.

- Avoid touching hot surfaces: The fuser unit gets extremely hot during operation. Avoid touching it until it has cooled down completely.

- Use proper personal protective equipment (PPE): When handling toner, use gloves and a mask to avoid inhalation of toner dust. Toner dust can irritate the lungs and skin.

- Handle paper carefully: Avoid paper cuts by carefully removing jammed paper. Use tools if needed to prevent injury.

- Follow manufacturer instructions: Always consult the copier’s manual for safety instructions and maintenance procedures.

- Proper grounding: Ensure the copier is properly grounded to prevent electric shock. This is usually handled during installation.

Remember, safety is not a suggestion; it’s a necessity. Taking these precautions can prevent accidents and ensure a safe working environment.

Q 6. How do you diagnose and resolve fuser unit problems?

The fuser unit is a critical component, responsible for melting the toner onto the paper. Problems with the fuser unit can result in various printing issues.

Diagnosing fuser unit problems:

- No toner fusing: Prints are light, toner doesn’t adhere, or toner rubs off easily. This often indicates a problem with the fuser temperature, pressure rollers, or internal heating element.

- Overheating: The fuser unit may overheat and cause a malfunction. This can be due to a faulty thermal fuse, a malfunctioning temperature sensor, or simply prolonged heavy use.

- Burn marks or streaks: Burn marks or streaks on prints indicate that the fuser unit is too hot or has pressure problems.

Resolving fuser unit problems:

- Check the temperature: Many copiers have internal temperature sensors; use diagnostic tools or the machine’s control panel to verify the fuser temperature.

- Inspect the pressure rollers: Check the pressure rollers for wear, damage, or dirt. Replace or clean as necessary.

- Check the heating element: This requires technical expertise. The heating element’s resistance should be checked using a multimeter to diagnose problems. Replacement usually requires professional assistance.

- Replace the fuser unit: If the problem persists despite checks and cleaning, replacing the entire fuser unit might be necessary. This is best left to qualified technicians.

When dealing with fuser unit issues, prioritize safety. The fuser unit gets extremely hot, so allow it to cool down completely before handling. If you are not comfortable working with the fuser unit, always call a qualified technician for assistance.

Q 7. What are the common causes of blurry prints?

Blurry prints are a frustrating issue, often caused by a combination of factors:

- Drum problems: Scratches, debris, or static discharge on the photosensitive drum can cause blurry images. Cleaning or replacing the drum is often the solution.

- Toner issues: Low toner, improperly installed toner cartridges, or low-quality toner can result in faint or blurry prints.

- Roller problems: Worn, dirty, or damaged transfer rollers can interfere with the toner transfer to the paper, resulting in blurry or uneven prints. Cleaning or replacing the rollers might be needed.

- Fuser unit problems: (See answer to question 6) Incorrect fuser temperature can lead to smudging and blurry images.

- Paper issues: Using the wrong type or quality of paper can affect print clarity. Moisture in the paper can lead to uneven ink distribution.

- Mirror or lens contamination: If the copier uses a mirror or lens system, dust or smudges on these components can affect image sharpness.

Troubleshooting blurry prints involves systematically checking each component. Start with the simplest fixes, like checking toner levels and cleaning the rollers, then move on to more complex issues if necessary.

Q 8. How do you clean and maintain copier components?

Cleaning and maintaining copier components is crucial for optimal performance and longevity. This involves regular cleaning of external surfaces, such as the glass platen and feeder tray, using a soft, lint-free cloth and glass cleaner. Internal components require more specialized attention. For instance, the drum unit, which is very sensitive to scratches and dust, needs to be carefully cleaned with a specialized cleaning kit following the manufacturer’s instructions. Never use abrasive materials. Regular cleaning of the corona wires (using a specialized cleaning brush) and the fuser unit (carefully wiping away any toner residue) are also vital. Remember always to power down the copier before any cleaning task involving internal parts to prevent electrical shocks. Finally, proper disposal of used cleaning materials is essential for environmental responsibility.

For example, imagine leaving toner dust uncleaned on the drum; it could lead to blurry prints and eventually damage the drum itself. Regular cleaning prevents such issues and extends the life of the copier.

Q 9. What is the function of the primary corona wire?

The primary corona wire is a vital component in the xerographic process. It’s a high-voltage wire that applies a uniform electrostatic charge to the photoreceptor drum (OPC drum). This charge is essential because it prepares the drum’s surface to receive the toner. Without a properly functioning primary corona wire, the toner won’t adhere to the drum, resulting in blank or partially printed pages. Think of it as the ‘magnet’ attracting the toner to the drum. A weak charge from a dirty or damaged corona wire leads to inconsistent toner distribution and poor image quality.

Maintaining the cleanliness of the primary corona wire is crucial, as toner particles and dust accumulating on it can significantly reduce its effectiveness. Regular cleaning, as part of routine maintenance, is therefore vital.

Q 10. Explain the role of the transfer roller.

The transfer roller’s role is to transfer the toner from the photoreceptor drum (OPC drum) onto the paper. After the toner is electrostatically attached to the drum, the transfer roller, charged oppositely to the drum, attracts the toner particles and transfers them to the paper passing between the drum and roller. It’s a critical step where the image is effectively ‘moved’ from the drum to the paper. A malfunctioning transfer roller could lead to incomplete image transfer, resulting in faded prints or toner left on the drum.

Imagine trying to transfer a drawing from one sheet of paper to another by simply pressing them together – often it doesn’t work well. The transfer roller provides a controlled electrostatic process that makes this transfer efficient and reliable.

Q 11. How do you perform routine maintenance on a copier?

Routine maintenance on a copier is key to preventing major issues and ensuring smooth operation. This includes regular cleaning of external surfaces, checking the toner level and replacing cartridges when needed, visually inspecting the drum for any damage, and verifying proper paper feeding. Additionally, it involves checking the fuser unit for any wear and tear or toner spills. Many copiers have built-in maintenance alerts or counters that indicate when specific components need attention. Following the manufacturer’s maintenance schedule, often found in the copier’s manual, is paramount. Keeping a log of maintenance tasks performed also aids in proactive upkeep and troubleshooting.

For instance, routinely checking the paper path helps to prevent paper jams. A little preventative maintenance saves a lot of downtime later.

Q 12. What is the function of the developer unit?

The developer unit is responsible for mixing the toner with a carrier material (usually magnetic beads) and transferring it to the photoreceptor drum. It’s like a ‘toner dispenser’. This process ensures even toner distribution across the drum surface. The developer unit manages the flow of toner onto the charged drum, ensuring that the correct amount of toner adheres to the areas of the drum that correspond to the image. Without a properly functioning developer unit, the image may appear faint, uneven, or missing altogether. A malfunctioning developer unit may cause toner splatter, streaks or toner starvation.

Think of it as the paintbrush applying color to the canvas – if the brush is clogged or empty, the painting will suffer.

Q 13. How do you replace a toner cartridge?

Replacing a toner cartridge is usually a straightforward process. First, power off the copier and unplug it. Then, locate the toner cartridge access door, typically clearly marked. Open the door, gently remove the old cartridge, making note of its orientation. Carefully take the new cartridge out of its packaging, avoiding contact with the toner powder. Insert the new cartridge, ensuring it’s properly seated and aligned. Close the door, plug the copier back in, and power it on. The copier might require a few moments to recognize the new cartridge.

It’s important to handle toner cartridges carefully to avoid toner spillage and inhalation. Always follow the manufacturer’s instructions.

Q 14. What are the differences between various toner types?

Different toner types cater to various needs and printing environments. Factors such as print volume, paper type, and desired image quality influence toner selection. Common types include:

- Standard Toner: A general-purpose toner, suitable for everyday use, offering a balance of cost and quality.

- High-Yield Toner: Designed for high-volume printing, offering a larger toner capacity for fewer replacements.

- Color Toner: Used in color copiers/printers, available in CMYK (Cyan, Magenta, Yellow, Black) to produce full-color prints.

- Specialty Toner: For specialized applications, such as glossy or metallic printing, offering unique effects. Examples are often labeled as such on the cartridge.

Choosing the right toner is crucial for optimal print quality and copier performance. Using the wrong type of toner can lead to subpar print quality or even damage the copier’s components.

Q 15. Describe the different types of copier drums and their functions.

Xerographic copiers utilize different types of drums, each designed for specific functionalities and performance characteristics. The core function of all copier drums is to receive a static electrical charge, then accept toner particles, and finally transfer that toner to the paper. Here are some common types:

- Organic Photoconductor (OPC) Drums: These are the most common type. They are made of a light-sensitive organic material that changes its electrical conductivity when exposed to light. When the image is projected onto the drum, the exposed areas become conductive, losing their charge, while the unexposed areas remain charged, attracting toner. They offer a good balance of cost and performance.

- Selenium Drums: These drums utilize inorganic selenium as the photoconductive material. Selenium drums are known for their durability and long life, but they are more expensive and less sensitive to light than OPC drums. They are less common in modern machines due to environmental concerns.

- Organic Photoconductor (OPC) Drums with a cleaning layer: These drums incorporate a special cleaning layer that assists in removing residual toner, improving image clarity and reducing the frequency of cleaning. This layer helps improve the lifespan of the drum and minimizes wear and tear.

The choice of drum depends on factors like copier model, print volume, and desired image quality. For example, high-volume copiers often utilize more durable selenium or advanced OPC drums for extended operational life.

Career Expert Tips:

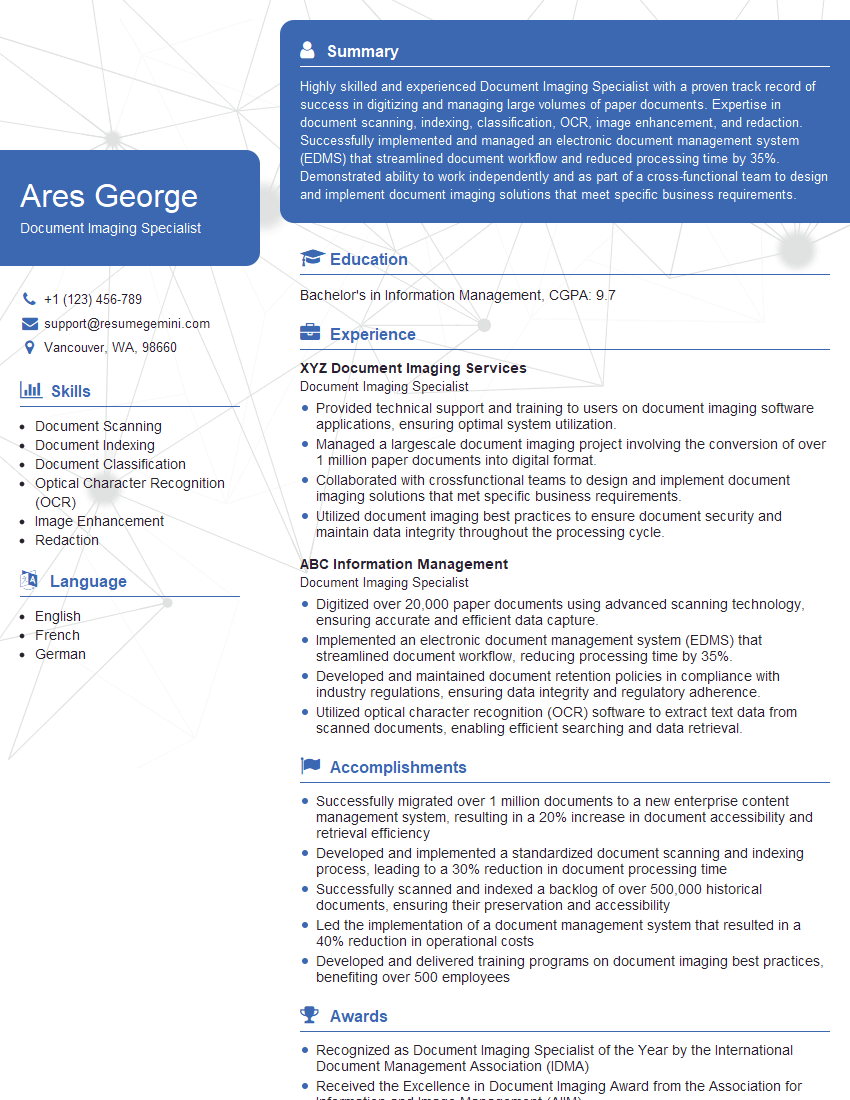

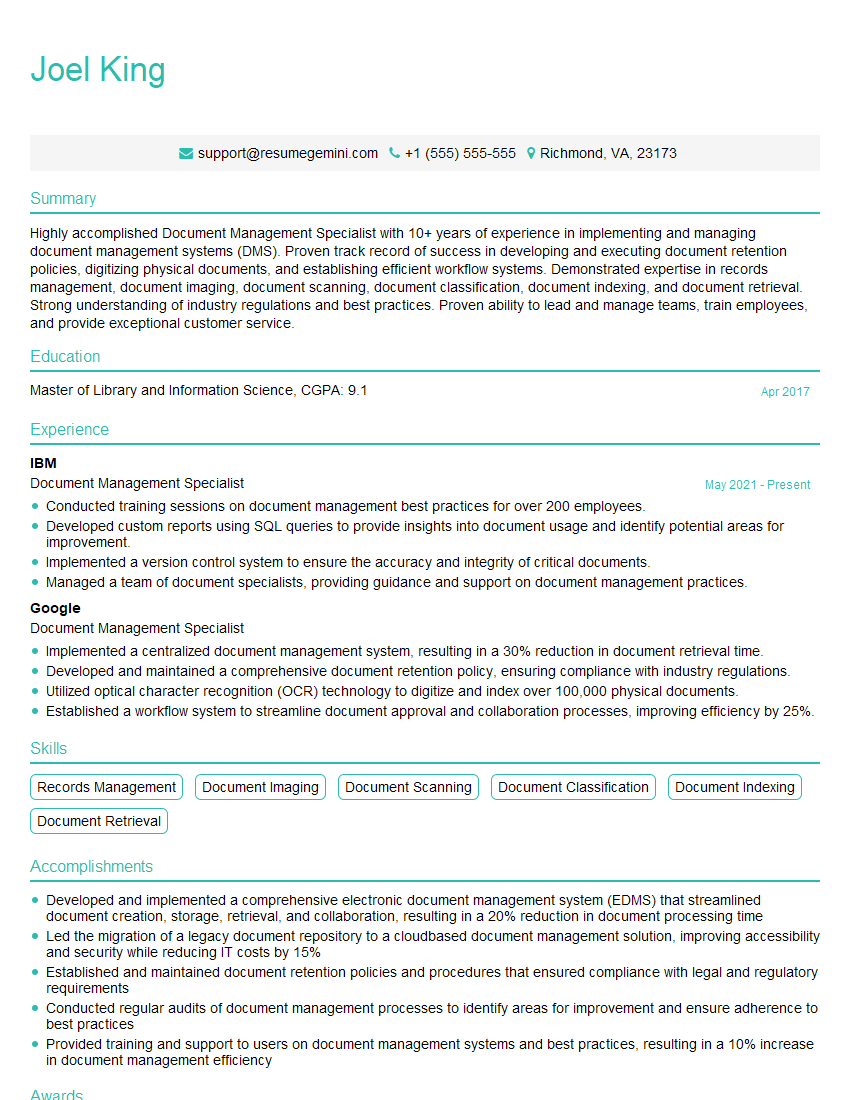

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you diagnose and fix a drum unit issue?

Diagnosing a drum unit issue begins with observing the print output. Look for common problems such as:

- Ghost images: Faint, previous images appearing on current prints indicate insufficient cleaning of the drum.

- Streaks or lines: These often suggest damage or wear on the drum surface or cleaning blade.

- Background noise or black specks: This could signify toner sticking to the drum incorrectly or a problem with the drum’s corona wire.

- Blank pages or incomplete images: Problems with the charging system or drum’s photoconductivity could be the cause.

Troubleshooting steps involve:

- Visual inspection: Carefully examine the drum for scratches, marks, or visible damage. Even minor imperfections can affect print quality.

- Cleaning: Carefully clean the drum using the manufacturer’s recommended cleaning tools and procedure. Never use abrasive materials.

- Check the corona wires: Inspect the corona wires for wear or damage. These wires are responsible for charging the drum and need to be clean and properly positioned.

- Test the cleaning blade: A worn or damaged cleaning blade will leave residual toner on the drum. Replace if needed.

- Replace the drum unit: If problems persist after cleaning and inspection, replacement may be necessary. Often it’s more cost effective to replace the entire drum unit than to try fixing individual components.

Remember, always consult the copier’s service manual for specific troubleshooting steps and safety precautions. Improper handling of the drum unit can lead to further damage.

Q 17. What are the common causes of static discharge issues?

Static discharge issues in copiers are frequently caused by environmental factors and machine maintenance issues. Here are some common causes:

- Low humidity: Dry air increases static electricity buildup. This makes toner particles more likely to cling to unintended areas, resulting in ghost images or uneven toner distribution.

- Dirty rollers or drums: Accumulated toner and debris can act as insulators, hindering the flow of electricity and causing static discharge.

- Faulty corona wires: The corona wires are responsible for providing the initial charge to the drum. Damage or deterioration will impair this process, leading to static problems.

- Improper grounding: A poorly grounded copier can become charged, leading to static discharge and potential shocks.

- Dust and debris: Dust and other particles in the copier’s environment can contribute to static buildup.

Think of it like rubbing a balloon on your hair – low humidity acts like the dry hair, making it easier to build up static charge.

Q 18. Explain the function of the separation pad.

The separation pad plays a crucial role in the xerographic process by transferring the toner image from the drum to the paper. It’s a highly sensitive component with a slightly sticky surface that attracts the toner particles. As the paper passes between the drum and the separation pad, the toner is carefully transferred onto the paper without disturbing the rest of the image. Imagine it as a very precise adhesive that only grabs the toner and leaves the drum clean. The separation pad’s material is designed to provide the right amount of adhesion to ensure a clean transfer and prevent toner from sticking to the wrong places.

A worn or damaged separation pad will result in poor image transfer, resulting in light prints, uneven toner distribution, and toner specks on the drum. Regular inspection and replacement of the separation pad are essential to maintain consistent print quality.

Q 19. How do you diagnose and resolve problems with image quality?

Diagnosing image quality problems is a systematic process. Start by carefully examining the printed output for:

- Light or faded images: This might indicate insufficient toner, issues with the toner supply, or problems with the drum’s charging system.

- Dark areas or toner build-up: This suggests too much toner, a cleaning issue, or potential problems with the separation pad.

- Streaks or lines: These usually point to drum or cleaning blade issues, or possibly debris on the drum.

- Ghost images: These are faint remnants of previous prints, indicating a cleaning problem within the system.

- Uneven toner distribution: This often points to problems with the drum’s charging system or inconsistencies in the roller pressure.

Resolving these issues can require a combination of approaches:

- Cleaning the drum and rollers: Clean all relevant components as per the manufacturer’s instructions.

- Inspecting and replacing worn parts: Check the cleaning blade, drum, and separation pad for wear. Replace any components exhibiting damage.

- Adjusting toner density settings: The copier may have settings that control the amount of toner used. Adjust as needed based on the printing problem.

- Checking toner supply and quality: Make sure you have enough toner and that it’s of good quality. Old or incompatible toner may cause problems.

- Assessing the charging system: Inspect corona wires and high voltage components for proper function.

Remember that a systematic approach that eliminates possible causes one by one is key to resolving image quality issues. Sometimes, it may involve several of the steps above.

Q 20. What is the importance of maintaining proper humidity levels?

Maintaining proper humidity levels is crucial for optimal xerographic copier performance. Low humidity can lead to excessive static electricity, resulting in problems like toner sticking to unwanted areas, causing ghost images, and uneven toner distribution. High humidity, on the other hand, can cause toner to clump together, resulting in smudging and poor image quality. The ideal humidity range is typically between 40% and 60%.

Think of it like this: too dry, and everything is too charged, like a dry winter day with static cling. Too wet, and everything gets sticky, making it hard to keep things neat.

Monitoring and controlling humidity is usually done through environmental control systems within the copier room. Humidifiers or dehumidifiers can be used to adjust the levels as needed to maintain the ideal operating range for your copier.

Q 21. Describe different methods for cleaning the glass platen.

Cleaning the glass platen is essential for ensuring clear, sharp copies. There are several methods, but always follow the manufacturer’s instructions for your specific machine.

- Static-cling Cleaning: A lint-free cloth lightly sprayed with a suitable glass cleaner works well. Use gentle, overlapping strokes to avoid streaks.

- Isopropyl Alcohol Cleaning: For more stubborn marks, use isopropyl alcohol (IPA) on a lint-free cloth. IPA is effective at dissolving many types of residue. However, always ensure the machine is turned off and allow sufficient drying time before operation.

- Specialized Cleaning Wipes: Many copier manufacturers offer specialized cleaning wipes formulated specifically for their machines’ platens. These are convenient and designed to avoid damaging the glass or leaving residue.

Important Considerations:

- Avoid abrasive cleaners: Harsh chemicals and abrasive materials can scratch the glass, leading to poor image quality.

- Always use a lint-free cloth: Lint can transfer onto the glass and appear on your copies.

- Work in a clean environment: Avoid cleaning the platen in a dusty area.

Regular cleaning prevents smudges and dust from affecting the image quality, ensuring consistently clear and crisp copies.

Q 22. What are the safety precautions involved in handling waste toner?

Handling waste toner requires stringent safety measures because it’s a fine powder that can be irritating to the lungs and skin. Think of it like handling flour, but with much more serious consequences if inhaled.

- Personal Protective Equipment (PPE): Always wear a respirator mask rated for fine particles (like an N95 or better), gloves, and eye protection. This prevents inhalation and skin contact.

- Proper Containment: Use appropriate containers designed for toner waste. Never use regular trash bags as they can easily tear and release the toner into the air. The containers should be clearly labeled and sealed securely.

- Ventilation: Work in a well-ventilated area or use a local exhaust ventilation system to remove airborne toner particles. This is crucial to avoid inhalation hazards.

- Disposal: Follow all local regulations and guidelines regarding the proper disposal of waste toner. Often, this involves contacting a specialized waste disposal company.

- Hygiene: Wash your hands and exposed skin thoroughly after handling toner waste.

For example, imagine a scenario where you’re replacing a toner cartridge. Failing to wear a respirator could lead to respiratory irritation or even more serious health issues. Proper handling is paramount for your safety and the safety of those around you.

Q 23. How do you identify and replace worn or damaged parts?

Identifying and replacing worn or damaged parts involves a combination of visual inspection and understanding the copier’s operational characteristics. It’s like diagnosing a car problem – you need to know what to look for.

- Visual Inspection: Look for signs of wear such as cracks, scratches, or discoloration on parts like rollers, fusers, and transfer belts. Check for any physical damage or misalignment.

- Performance Indicators: Watch for recurring print issues. For example, consistent streaks on prints could indicate a worn-out drum, while poor image quality might suggest a problem with the fuser.

- Service Manuals and Diagrams: Copier service manuals (often available online) provide detailed schematics and instructions for part replacement. They’re like the repair manual for your copier. Using the diagrams, locate the faulty part precisely.

- Part Numbers: Each part has a unique identification number. Using this number will ensure that you’re ordering the correct replacement part.

- Proper Replacement: Follow the service manual’s instructions carefully. Sometimes this involves special procedures or tools. Improper replacement can damage other components.

For instance, if you see a roller is visibly scuffed or cracked, you know it needs replacing to prevent further damage and ensure consistent print quality. Always refer to the service manual for detailed instructions.

Q 24. How do you perform a routine preventative maintenance check?

Routine preventative maintenance (PM) for a xerographic copier is essential to keep it running smoothly and efficiently. Think of it like regular servicing for your car – it’s preventative rather than reactive.

- Cleaning: Clean the exterior of the machine, removing dust and debris. Vacuum the inside carefully to remove toner dust.

- Roller Cleaning: Clean the primary charge corona wire, transfer rollers, and other rollers with a specialized cleaning solution. These rollers are vital for proper toner transfer.

- Toner Cartridge Inspection: Check the toner cartridge level and replace if needed.

- Fuser Unit Inspection: Check the fuser unit for any signs of damage or wear, especially the pressure roller.

- Sensor Checks: Verify the functionality of various sensors (explained in the next question). A malfunctioning sensor can lead to many problems.

- Test Prints: Run test prints to check image quality and overall performance.

A regular PM schedule, perhaps monthly or quarterly, can significantly extend the life of your copier and minimize costly repairs down the road. Think of it as an investment in your equipment’s longevity.

Q 25. Explain the function of the various sensors in a copier.

Copiers use a variety of sensors to monitor their operation and ensure proper functioning. These sensors are like the copier’s ‘eyes and ears’, providing vital feedback.

- Toner Level Sensor: This sensor detects the toner level in the cartridge and alerts the user when it’s low or empty.

- Paper Sensors: These detect the presence and type of paper in the tray, preventing jams and ensuring proper paper feeding.

- Drum Sensors: Monitor the condition and rotation of the imaging drum, crucial for image formation.

- Fuser Temperature Sensor: Ensures the fuser unit reaches and maintains the correct temperature for toner fusing.

- Door/Cover Sensors: Detect if doors or covers are open, preventing operation to ensure safety.

- Optical Sensors: These sensors are used in various stages of the printing process. For example, one detects the presence of a jam.

If a sensor malfunctions, it can cause the copier to misoperate or produce errors. For example, a faulty paper sensor could cause paper jams. Regular testing and maintenance of these sensors are crucial for reliable operation.

Q 26. How would you handle a situation where a copier is consistently malfunctioning?

Handling consistently malfunctioning copiers requires a systematic approach. It’s like detective work – you need to gather clues and eliminate possibilities.

- Detailed Error Logs: Check the copier’s error logs for recurring error codes. This provides valuable clues about the problem’s root cause.

- Replicate the Problem: Try to reproduce the malfunction to understand the conditions that trigger it.

- Systematic Troubleshooting: Use the service manual as a guide for troubleshooting the specific error codes.

- Component Testing: If necessary, test individual components like the drum, fuser, and rollers to isolate the faulty part.

- External Factors: Check external factors such as power supply, network connectivity, and environmental conditions.

- Contact Support: If you cannot resolve the issue, contact the manufacturer’s support or a qualified service technician.

For example, imagine a copier consistently producing streaks on printouts. By examining the error logs and testing different components, you could identify a worn-out drum or a problem with the toner delivery system. This systematic approach ensures efficient and effective troubleshooting.

Q 27. What are some common network connectivity issues related to copiers?

Network connectivity issues with copiers are common and can range from simple configuration problems to more complex network infrastructure issues.

- IP Address Conflicts: The copier might have an IP address that conflicts with another device on the network.

- Network Cabling Problems: Damaged or incorrectly connected network cables can disrupt connectivity.

- Firewall Issues: Firewalls can block communication between the copier and other network devices.

- Driver Issues: Incorrectly installed or outdated drivers can prevent the copier from communicating with computers.

- DNS Issues: Problems with the Domain Name System can prevent the copier from resolving hostnames.

- Network Security Issues: Network security policies can sometimes restrict access to the copier.

For example, if the copier is unable to print from a particular computer, you might suspect a driver issue on that computer, or a firewall rule preventing communication. Checking network settings and drivers often resolves these problems.

Q 28. Describe the process of troubleshooting a copier that won’t power on.

Troubleshooting a copier that won’t power on requires a methodical approach to eliminate potential causes. It’s like troubleshooting a simple electrical appliance.

- Check the Power Cord and Outlet: The most common cause is a simple problem: Ensure the power cord is securely plugged into both the copier and the wall outlet. Test the outlet with another device to rule out a faulty outlet.

- Check the Circuit Breaker: A tripped circuit breaker can cut power to the copier. Check the breaker box for any tripped breakers and reset them if necessary.

- Power Supply Issues: Examine the power supply unit itself for any visible damage.

- Internal Fuses: Some copiers have internal fuses that may have blown. Consult the service manual for their location and replacement procedure.

- Internal Wiring: If the above steps don’t resolve the issue, there might be a problem with the copier’s internal wiring. This requires expert-level intervention.

For example, if the outlet is faulty, the copier won’t power on regardless of the condition of the copier itself. Always check the simplest things first before moving on to more complex troubleshooting steps.

Key Topics to Learn for Xerographic Copier Operation Interview

- Understanding the Xerographic Process: Master the fundamental steps of the xerographic process, from electrostatic charging to toner fusion. Be prepared to explain each stage and its importance.

- Copier Maintenance and Troubleshooting: Familiarize yourself with common copier malfunctions, preventative maintenance procedures, and basic troubleshooting techniques. Practice explaining your approach to problem-solving in a clear and concise manner.

- Toner and Fuser Unit Management: Understand the different types of toner, their properties, and how to properly handle and replace them. Know how fuser units function and the signs indicating they need replacement or maintenance.

- Paper Handling and Jam Clearance: Be proficient in identifying and resolving paper jams, understanding the causes of paper jams, and ensuring smooth paper feed and output. This includes understanding different paper types and their compatibility with the copier.

- Digital Workflow Integration: Learn how xerographic copiers integrate with digital workflows, including scanning, networking, and print management software. Be ready to discuss your experience with different interfaces and software.

- Safety Procedures and Regulations: Demonstrate knowledge of relevant safety protocols and regulations surrounding copier operation and maintenance, including handling toner and electrical components safely.

- Copier Technology and Features: Explore the various features of modern xerographic copiers, such as duplex printing, color printing, finishing options (stapling, hole punching), and advanced scanning capabilities. Understanding the benefits and applications of each feature is key.

Next Steps

Mastering Xerographic Copier Operation opens doors to a rewarding career with excellent growth potential. This skillset is highly valued across various industries, offering opportunities for advancement and specialization. To maximize your job prospects, it’s crucial to present your qualifications effectively. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. We strongly recommend using ResumeGemini, a trusted resource, to build a professional and impactful resume. ResumeGemini offers examples of resumes tailored specifically to Xerographic Copier Operation roles, helping you showcase your skills and experience in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO