Unlock your full potential by mastering the most common Yard Spotting interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Yard Spotting Interview

Q 1. Explain the process of safely coupling and uncoupling rail cars.

Safely coupling and uncoupling rail cars is crucial for efficient and safe rail operations. It involves a series of steps designed to prevent accidents and damage. Think of it like connecting and disconnecting large, heavy Lego blocks – precision and caution are key.

- Preparation: Before approaching the cars, ensure the brakes are set on both cars to be coupled. Visually inspect the couplers for any damage or obstructions. This step prevents accidental movement.

- Coupling: Carefully position the locomotives or shunters to align the couplers. Use the coupler’s mechanism to join the cars, ensuring a firm connection. A proper connection will have a noticeable ‘click’ or ‘thunk’. You should never force a connection.

- Uncoupling: To uncouple, you’ll typically use a lever or pin mechanism located on the coupler. This releases the connection between the cars. After uncoupling, verify separation and ensure the cars remain stationary by maintaining brake settings.

- Post-coupling/uncoupling check: After either coupling or uncoupling, always perform a final visual check to ensure the cars are securely coupled or safely separated, with brakes engaged as needed. Listen for any unusual sounds that might indicate a problem.

For example, in a busy switching yard, a misaligned coupler can lead to delays and potential derailments. Following these procedures meticulously avoids such issues, ensuring both operational efficiency and safety.

Q 2. Describe your experience with different types of yard switching maneuvers.

My experience encompasses a wide range of yard switching maneuvers, each demanding a different approach and skill set. Think of it like conducting an orchestra – each instrument (railcar) needs to be positioned precisely and in sync for the entire piece (train) to work.

- Kickbacks: This involves using momentum to shunt a single car or a small group of cars into a specific track. It requires precise calculation of speed and distance – too much force can cause a derailment, too little and the cars won’t reach their destination.

- Running Switches: This involves switching cars while the train is moving. This is a highly skilled maneuver, requiring precise timing and coordination to avoid collisions, often used in high-volume yards to increase efficiency.

- Chain Switches: This is a series of connected switching moves, often involving multiple tracks and numerous cars. Careful planning and execution are crucial to prevent congestion and collisions. I’ve coordinated complex chain switches involving dozens of cars, optimizing for efficiency and minimal downtime.

- Spotting: Precisely placing individual cars in their assigned locations within the yard. Accuracy is critical here to ensure efficient loading and unloading.

In one instance, I successfully navigated a complex chain switch involving over 30 cars, efficiently re-arranging them for different outbound trains, minimizing delays, and preventing any incidents.

Q 3. How do you prioritize tasks in a busy yard environment with multiple incoming and outgoing shipments?

Prioritizing tasks in a busy yard environment requires a systematic approach. It’s like managing a very complex puzzle where each piece (shipment) must find its place in a timely manner.

- Urgency: I prioritize shipments with tight deadlines or those requiring immediate attention, such as perishable goods or time-sensitive deliveries.

- Destination: I group shipments heading to the same destination, streamlining the movement of cars and reducing unnecessary switching.

- Track availability: I consider track availability, optimizing car placement to ensure smooth flow and prevent bottlenecks.

- Safety: Safety is paramount. If a task presents a safety hazard, it takes precedence, even if it means a slight delay to other tasks.

For instance, if there’s a shipment of refrigerated goods nearing its temperature limit, it takes precedence over other shipments, regardless of their arrival time. I use a combination of yard management systems and personal judgment to balance efficiency and safety.

Q 4. What safety procedures do you follow when operating in a yard environment?

Safety is my top priority. I follow a rigorous set of procedures, constantly vigilant and aware of my surroundings. Think of it as being a surgeon – every step must be precise and measured to avoid any errors.

- Pre-shift inspection: I always begin by inspecting the locomotive and other equipment for any mechanical issues. This ensures everything is in optimal working order.

- Communication: Clear communication with ground crews, dispatchers, and other operators is vital to avoid accidents. I always use established communication channels and protocols.

- Visibility: Ensuring clear visibility is vital; I use appropriate lighting and signaling devices at all times.

- Awareness: I maintain constant awareness of my surroundings, including the movement of other equipment and personnel. I use a combination of visual checks and listening for any unusual sounds.

- Rules and regulations: I strictly adhere to all company safety rules and regulations, and I actively participate in safety training.

For example, I once noticed a small crack in a coupler during my pre-shift inspection, preventing a potential derailment later in the day. Proactive safety checks are essential.

Q 5. How do you ensure the accuracy of load assignments in the yard?

Ensuring accurate load assignments is vital for efficient operations and avoiding costly errors. It’s like assembling a puzzle; each piece must be in its correct location.

- Cross-referencing: I meticulously cross-reference waybills, manifests, and electronic tracking systems to verify the accuracy of load assignments.

- Visual inspection: I perform a visual inspection of the car and its contents to match it with its documentation. This can help detect any discrepancies or errors.

- Verification with dispatch: I communicate with the dispatch office to clarify any uncertainties or discrepancies before proceeding.

- Double checking: I always double-check my work, ensuring all information matches and there are no conflicts.

I once discovered a mismatch between a waybill and the actual contents of a car. By promptly identifying and correcting this error, I prevented a potential delay in delivery and ensured the correct handling of the goods.

Q 6. Explain your experience using yard management systems (YMS).

Yard Management Systems (YMS) are invaluable tools for streamlining yard operations. They are like a control tower for the entire yard, providing real-time information and control.

My experience with YMS includes using them to:

- Track car locations: Real-time tracking of car locations, significantly improving efficiency in locating and moving cars.

- Manage assignments: Efficiently managing car assignments, ensuring cars are placed in the correct locations for loading and unloading.

- Optimize schedules: Optimizing switching schedules to minimize delays and increase throughput.

- Generate reports: Generating reports on yard activity, providing valuable data for analysis and improvement.

I’m proficient in using YMS software to plan and execute complex yard switching operations, enhancing efficiency and minimizing delays. The data analysis capabilities of YMS help identify bottlenecks and make informed decisions to improve operational performance.

Q 7. Describe your experience with different types of yard equipment (e.g., shunters, tractors, forklifts).

I have extensive experience operating various yard equipment, each with its own unique characteristics and challenges. Think of them as specialized tools, each best suited for a particular task.

- Shunters (switch engines): I’m proficient in operating shunters for coupling, uncoupling, and moving cars within the yard. I understand the nuances of controlling these powerful machines, ensuring precise movements in tight spaces.

- Tractors: I’m experienced in using yard tractors for moving trailers and containers around the yard. This involves maneuvering heavy loads efficiently and safely.

- Forklifts: I have experience with forklifts for handling smaller loads and materials. I understand the safety protocols involved in operating this equipment, especially in congested areas.

In one situation, I used a combination of a shunter and yard tractor to efficiently move a large number of containers to their designated locations, minimizing congestion and completing the task within a tight timeframe.

Q 8. How do you handle unexpected delays or equipment malfunctions in the yard?

Unexpected delays and equipment malfunctions are unfortunately common in yard spotting. My approach is proactive and multi-faceted. First, I assess the situation: What’s broken? How critical is it to the overall workflow? How long is the projected downtime?

For minor issues, like a minor software glitch on a yard management system, I might have a workaround already in place, or I’ll contact IT support immediately. For major equipment failures, I’ll follow established protocols, starting with securing the area for safety. I then initiate the repair process – contacting maintenance, potentially finding a temporary replacement (if feasible), and re-routing operations to minimize disruption. For example, if a forklift breaks down during peak hours, I might temporarily redirect tasks to other available equipment and personnel, while prioritizing the most urgent tasks. The key is clear communication and a flexible approach, adapting to the situation rather than being paralyzed by the unexpected.

Thorough preventative maintenance is crucial in minimizing these events. Regular equipment checks, operator training, and using the right equipment for the job are all critical preventative measures.

Q 9. What methods do you use to communicate effectively with other yard personnel?

Effective communication is the backbone of efficient yard operations. I use a multi-channel approach, selecting the best method depending on the urgency and context.

- Two-way radios: For immediate, real-time communication regarding urgent issues like obstructing vehicles or safety concerns. Imagine needing to quickly alert other operators about a spill or a blocked pathway – radios are indispensable.

- Yard management system (YMS): For tracking tasks, assigning jobs, and monitoring progress. The YMS acts as a central hub for information, providing updates and facilitating coordinated efforts.

- Face-to-face communication: For complex issues or when a more detailed explanation is needed, direct communication remains highly effective. This allows for immediate clarification and a quicker resolution.

- Regular team meetings: This is essential for sharing information, addressing concerns, and providing updates on process changes. Open communication fosters a collaborative environment.

Regardless of the method, clarity and conciseness are essential. I always confirm understanding to prevent miscommunication. Think of it like a well-oiled machine – every part needs to be aware of its role and how it interacts with the others.

Q 10. How do you identify and report potential safety hazards in the yard?

Safety is paramount in yard operations. My approach to identifying and reporting potential hazards involves proactive observation, regular inspections, and a culture of reporting.

- Daily inspections: I conduct regular walk-throughs to identify potential hazards like damaged equipment, uneven terrain, or poorly stacked materials. These inspections are documented and reported.

- Near-miss reporting: Encouraging employees to report near misses is vital. These reports highlight areas that need attention, preventing future accidents.

- Regular training: Employees are regularly trained on safety protocols and emergency procedures. This includes training on the proper use of equipment, hazard recognition, and emergency response.

- Clear communication channels: Employees are provided clear avenues for reporting hazards. These might include a designated supervisor, safety officer, or a dedicated reporting system.

For example, if I spot a cracked pavement, I’ll immediately report it to maintenance and place appropriate warning signs until it’s repaired. By acting proactively, we reduce the risk of accidents and create a safer work environment.

Q 11. Describe your experience with inventory management within a yard setting.

Inventory management is crucial for efficient yard operations. My experience involves utilizing both manual and automated systems to track inventory levels, location, and movement.

- Manual tracking: In some instances, particularly for smaller yards or specific items, manual tracking using spreadsheets or physical logs remains a reliable method. This requires meticulous attention to detail and regular updates.

- Automated systems: Larger yards frequently utilize yard management systems (YMS) that provide real-time inventory tracking, location identification, and automated reporting. This enhances accuracy and efficiency. These systems often incorporate barcodes or RFID tags for efficient item identification.

- Regular stocktaking: Physical inventory counts are conducted regularly to verify the accuracy of inventory records. Discrepancies are investigated and corrected to maintain accurate data.

Effective inventory management helps optimize space utilization, prevents stockouts, and reduces the risk of damage or loss. Accurate inventory data is essential for informed decision-making related to procurement and resource allocation.

Q 12. How do you maintain accurate records of yard movements and activities?

Maintaining accurate records of yard movements and activities is critical for accountability, efficiency, and regulatory compliance. My methods include:

- Yard Management System (YMS): Most modern yards use a YMS which automatically records activities such as container movements, equipment usage, and employee logins. These systems provide detailed audit trails and data for analysis.

- Manual logs: Supplementary manual logs can be useful for recording specific details or observations that may not be captured by the YMS. These need to be meticulously maintained and cross-referenced with the YMS data.

- GPS tracking: GPS tracking on equipment provides accurate location data and allows for the monitoring of equipment usage and movements. This data can be integrated with the YMS.

- Digital documentation: Images or videos of the yard layout, inventory, or any unusual occurrences can serve as valuable supplementary records.

Accurate record-keeping helps with tracking productivity, identifying bottlenecks, and ensuring compliance with security protocols.

Q 13. Explain your understanding of yard capacity and its impact on operations.

Yard capacity refers to the maximum amount of inventory or equipment a yard can effectively handle. Understanding yard capacity is crucial for optimizing operations and preventing congestion. Factors influencing yard capacity include:

- Physical space: The size of the yard and its layout.

- Equipment capacity: The number and type of equipment available, like forklifts and cranes.

- Workflow efficiency: The effectiveness of the processes and the efficiency of the yard team.

- Inventory density: How efficiently the yard space is used and materials are stacked.

Exceeding yard capacity leads to inefficiencies, delays, safety hazards, and increased costs. For example, overcrowding can make it difficult to access certain areas, causing delays in loading and unloading operations. Conversely, under-utilizing yard capacity leads to wasted space and resources. Proper capacity planning is essential for determining the optimal number of employees, equipment, and resources required for efficient operation.

Q 14. How do you ensure efficient space utilization within the yard?

Efficient space utilization is key to maximizing yard capacity and minimizing operational costs. My strategies include:

- Optimized Yard Layout: Designing a yard layout that facilitates smooth workflow and minimizes unnecessary movements. This includes strategically placing storage areas, loading docks, and equipment staging areas.

- Effective Stacking Techniques: Utilizing appropriate stacking methods to maximize vertical space and ensure stability. Proper stacking prevents damage and ensures safe access to stored items.

- Inventory Categorization: Organizing inventory based on frequency of access and type of goods. High-frequency items should be stored in easily accessible locations.

- Regular Inventory Audits: Periodically reviewing inventory to identify unused or obsolete items which can be removed to free up space.

- Technology Integration: Using YMS and other technology like GPS tracking to optimize space allocation and track inventory movement in real-time.

Think of it like organizing a closet: By carefully arranging items, you can fit more in while still ensuring easy access to what you need. The same principle applies to yard management, improving efficiency and reducing wasted space.

Q 15. Describe your experience with various load securing techniques.

Load securing is paramount in yard spotting to prevent damage and ensure safety during transportation. My experience encompasses a range of techniques, tailored to the specific cargo and transport method. For example, I’m proficient in using various types of straps, chains, and winches to secure different types of loads, from oversized equipment to standard shipping containers. I understand the importance of considering the weight distribution, center of gravity, and potential shifting during transit.

- Strapping: I’m skilled in using different types of straps, including ratchet straps, web straps, and cargo straps, ensuring they are appropriately tensioned and anchored securely to prevent slippage. This often involves calculating the required tension based on load weight and securing points.

- Chaining: I’m experienced with chain securing, understanding the proper use of shackles, binders, and other connecting hardware. Critical aspects include choosing the right chain grade for the load weight and ensuring proper chain lubrication to prevent breakage.

- Blocking and Bracing: I understand the importance of using wooden blocks or other materials to brace loads and prevent shifting, especially during transportation over uneven terrain. This method is particularly useful when dealing with oddly shaped or heavy cargo.

- Container Securing: My experience extends to securing intermodal containers onto chassis using twistlocks and ensuring proper alignment to prevent damage during transport.

I always prioritize safety and adhere to all relevant regulations and best practices for load securing to minimize risks.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle inclement weather conditions affecting yard operations?

Inclement weather significantly impacts yard operations. My approach involves a multi-pronged strategy prioritizing safety and efficiency.

- Safety First: High winds, heavy rain, or snow necessitate slowing down operations, potentially halting them entirely if conditions are too hazardous. Employee safety is always the top priority, and we would utilize appropriate personal protective equipment (PPE).

- Prioritization: Urgent shipments are prioritized during inclement weather. We would focus on securing already loaded vehicles and sheltering sensitive cargo, such as those susceptible to water damage.

- Equipment Maintenance: Regular maintenance of yard equipment, such as forklifts, is crucial, ensuring they can operate effectively in adverse conditions. This includes checking tire pressure and ensuring proper functioning of lights and wipers.

- Communication: Clear communication with drivers and other stakeholders is critical, providing updates on potential delays and informing them of any safety measures in place.

- Emergency Preparedness: Having a pre-determined plan for emergencies, including procedures for evacuation and securing equipment, is essential in managing severe weather events.

We utilize weather forecasts to anticipate potential challenges and proactively adjust our schedules and strategies to mitigate the impact of adverse conditions.

Q 17. What is your experience with maintaining yard cleanliness and organization?

Maintaining a clean and organized yard is crucial for efficiency and safety. My experience includes implementing and enforcing procedures to keep the yard functional and hazard-free.

- Designated Areas: Implementing a system of designated areas for different types of cargo, ensuring clear labeling and signage to reduce confusion and expedite retrieval.

- Regular Cleanups: Scheduling regular cleanups to remove debris, trash, and spilled materials, preventing accidents and keeping the yard tidy.

- Preventive Maintenance: Regular inspections of equipment and infrastructure to identify and address potential hazards promptly, ensuring a safe working environment.

- Inventory Management: Accurate inventory management and tracking system helps in efficient space utilization and minimizes the risk of misplaced items.

- Waste Management: Following established procedures for waste disposal, including recycling and proper handling of hazardous materials, complying with all environmental regulations.

A clean and well-organized yard not only improves efficiency but also creates a safer environment for all personnel and reduces the risk of accidents or damage to goods.

Q 18. How do you manage multiple assignments simultaneously in a fast-paced yard environment?

Managing multiple assignments simultaneously in a fast-paced yard environment requires strong organizational skills and effective time management. My approach involves:

- Prioritization: Identifying and prioritizing tasks based on urgency and importance, focusing on time-sensitive assignments first.

- Task Breakdown: Breaking down complex tasks into smaller, manageable steps to make them less overwhelming and easier to track.

- Delegation (if applicable): Delegating tasks when appropriate, ensuring clear communication and follow-up to ensure tasks are completed efficiently.

- Communication: Maintaining clear communication with team members and supervisors to ensure everyone is aware of my workload and potential bottlenecks.

- Flexibility: Adapting to changing priorities and unexpected events, prioritizing tasks dynamically as needed.

I’m comfortable working under pressure and handling multiple requests simultaneously, ensuring all tasks are completed accurately and efficiently, even during peak hours.

Q 19. Describe your problem-solving approach in a situation where a shipment is misplaced in the yard.

Misplaced shipments are a serious concern. My problem-solving approach involves a systematic and thorough investigation:

- Verify Information: First, I would double-check all documentation, including the shipping manifest, tracking numbers, and any available GPS data. This helps to identify the expected location of the shipment.

- Yard Search: Conduct a thorough search of the yard, utilizing any available yard management systems or technology to narrow down the search area. This might include physically checking designated areas or employing the use of yard scanners.

- Check Documentation: Review all relevant documentation, including loading and unloading records, to determine if any discrepancies occurred during the handling of the shipment.

- Involve Team: If the shipment cannot be located quickly, I would involve other team members or supervisors to assist in the search and expand the search area.

- Review Security Footage (if available): Check security camera footage to retrace the shipment’s movement and identify potential points of misplacement.

- Report and Document: Once the shipment is located, or if it remains missing, I would document the entire process, including steps taken and any findings, and report to the relevant stakeholders.

My aim is to resolve the issue swiftly, minimize disruption, and prevent similar incidents in the future. A thorough investigation is key to pinpointing the source of the error.

Q 20. How do you contribute to improving the overall efficiency of the yard?

Improving yard efficiency is a continuous process. My contributions include:

- Process Optimization: I actively identify bottlenecks and inefficiencies in existing processes and suggest improvements, such as optimizing traffic flow, streamlining loading/unloading procedures, and improving communication channels.

- Technology Adoption: I’m a proponent of using technology to enhance yard operations. This includes advocating for and utilizing yard management systems (YMS) to improve tracking, inventory management, and overall efficiency. I’m also comfortable working with GPS tracking and other technologies to improve the real-time visibility of shipments.

- Training and Development: I believe in training and development to enhance team efficiency. I willingly share my knowledge and skills with colleagues, helping them improve their proficiency and contributing to the overall improvement of yard operations.

- Proactive Problem Solving: I anticipate potential issues and proactively address them, preventing delays and disruptions. This includes regularly inspecting equipment, proactively addressing maintenance needs, and ensuring sufficient resources are available.

- Data Analysis: Using data analysis to identify trends, measure performance, and inform future improvements. I’d review metrics like turnaround time, dwell time, and error rates to pinpoint areas needing attention.

A continuous improvement mindset, focused on data-driven decision-making, is essential in driving up yard efficiency.

Q 21. What are your strategies for reducing the risk of accidents in the yard?

Reducing the risk of accidents is a top priority. My strategies include:

- Safety Training: Regular safety training for all personnel, emphasizing safe operating procedures for all equipment and stressing the importance of wearing appropriate PPE.

- Equipment Maintenance: Regular inspections and maintenance of all yard equipment, including forklifts, tractors, and other vehicles, to ensure they are in safe working order.

- Traffic Management: Implementing clear traffic management systems, including designated routes, speed limits, and traffic signals to minimize collisions and improve pedestrian safety.

- Hazard Identification and Mitigation: Regularly inspecting the yard for potential hazards, such as potholes, debris, and uneven surfaces, and taking prompt action to mitigate risks.

- Safe Operating Procedures: Enforcing and adhering to strict safe operating procedures for all yard activities, including loading, unloading, and maneuvering equipment.

- Emergency Response Plan: Establishing a clear emergency response plan, including procedures for handling accidents, injuries, and other emergencies.

A culture of safety, underpinned by proactive measures, is essential for minimizing accidents and creating a safe working environment.

Q 22. How do you adapt your approach to handling different types of cargo?

Handling diverse cargo requires a flexible approach. My strategy centers around understanding the specific needs of each type of cargo. For instance, oversized or heavy cargo requires careful placement to maintain structural integrity and prevent damage. This might involve using specific equipment like specialized forklifts or employing additional personnel for securement. Conversely, smaller, more fragile items require gentler handling and possibly additional padding or protective measures during spotting. I always consult the accompanying documentation – bills of lading, manifests, and any special handling instructions – to ensure I utilize the most appropriate methods for each load. This proactive approach minimizes risks associated with damage, delays, and safety incidents.

For example, when handling refrigerated containers, I meticulously check the temperature settings and ensure proper ventilation to prevent spoilage. Similarly, with hazardous materials, I adhere strictly to the safety regulations and handle them according to the designated protocols to ensure compliance and prevent accidents.

Q 23. Describe your experience working with different types of transportation equipment (e.g., trucks, trains).

My experience spans working with various transportation equipment including articulated trucks, semi-trailers, boxcars, and flatcars. Understanding the capabilities and limitations of each is crucial for efficient yard spotting. Articulated trucks, for example, require more maneuvering space due to their length. With boxcars, I’m aware of the limitations in loading and unloading procedures compared to trucks. This includes understanding weight distribution, clearance heights and the use of specific equipment like cranes or specialized lifting gear for certain cargo types on flatcars. I’ve also worked with intermodal containers, familiarizing myself with the different sizes and their specific handling requirements for stacking and securing them.

In one instance, I had to maneuver a large shipment of steel beams using a heavy-duty forklift and a specialized trailer. Accurate assessment of the weight and dimensions, coupled with precise maneuvering, was essential to ensure both the safety of the equipment and the integrity of the cargo.

Q 24. Explain your knowledge of relevant safety regulations and compliance procedures.

Safety is paramount in yard spotting. My understanding of OSHA regulations, including those pertaining to forklift operation, hazardous materials handling, and personal protective equipment (PPE) is extensive. I’m well-versed in conducting pre-shift inspections of equipment, following lockout/tagout procedures for maintenance, and adhering to speed limits and traffic rules within the yard. Regular training updates ensure my knowledge remains current. I understand the importance of maintaining a clean and organized workspace to prevent trips, slips, and falls and promptly reporting any unsafe conditions.

Furthermore, I’m familiar with the specific regulations related to handling various cargo types, such as dangerous goods regulations (IMDG Code and other relevant standards), ensuring that every step conforms to the highest safety standards.

Q 25. How do you stay informed about changes in yard operations and procedures?

Staying informed is vital. I attend regular safety meetings and training sessions, keeping up-to-date on best practices and any changes in company policies and procedures. I also actively participate in industry forums and read relevant publications to stay abreast of emerging trends and technologies in yard operations. Moreover, I maintain open communication with supervisors and colleagues, ensuring that any changes or updates are promptly communicated and understood.

For example, recently, our company implemented a new yard management system. I actively participated in the training program to learn how to use the system effectively and efficiently.

Q 26. How do you prioritize safety over speed in your work?

Prioritizing safety over speed is ingrained in my work ethic. While efficiency is important, it’s never at the expense of safety. My approach involves planning movements carefully, ensuring proper visibility, and adhering to speed limits. I avoid shortcuts and prioritize thorough assessments of the situation before acting. Using appropriate safety equipment like seat belts and high-visibility clothing, while conducting regular equipment checks before each shift, is critical. Regular self-assessment and training helps to embed this approach in my operational habits. A faster job that results in an accident is ultimately a far less efficient outcome.

For instance, even if I’m under pressure to meet a tight deadline, I will always take the time to ensure that the load is securely positioned and that the path is clear before moving heavy equipment.

Q 27. Describe a time you had to make a quick decision under pressure in the yard. What was the outcome?

During a severe thunderstorm, a stack of containers shifted slightly, posing a risk of collapse. The pressure was on as delays would impact a critical delivery. I quickly assessed the situation, prioritizing the immediate removal of the unstable containers and re-stacking them to ensure stability. I coordinated with other yard personnel and supervisors to effectively manage the situation and ensure that all workers were moved to a safe location away from the unstable containers. We used our emergency communication systems to inform all relevant parties about the situation. We successfully mitigated the risk with no injuries or damage, proving the value of quick thinking and teamwork.

Q 28. What are your career goals within the field of yard spotting?

My career goals involve progressing within the field of yard spotting, potentially taking on a supervisory role. I’m keen to enhance my expertise in yard management systems and safety procedures, and ideally, contribute to the implementation of new technologies aimed at optimizing yard operations and improving overall efficiency. I am also keen on acquiring a more formal qualification and certification in yard management or logistics, further enhancing my professional skillset.

Key Topics to Learn for Yard Spotting Interview

- Safety Procedures and Regulations: Understanding and applying all relevant safety protocols, including those related to equipment operation, hazardous materials, and emergency response procedures. This demonstrates your commitment to a safe work environment.

- Yard Layout and Organization: Knowing how to efficiently navigate and utilize a yard’s infrastructure, including understanding the location of various storage areas, loading docks, and access points. Be prepared to discuss strategies for optimizing space and workflow.

- Equipment Operation and Maintenance: Demonstrate familiarity with the types of equipment used in yard spotting (e.g., forklifts, yard tractors, etc.), including their operational procedures, maintenance requirements, and potential safety hazards. Practical experience is highly valued here.

- Load Planning and Optimization: Discuss your ability to effectively plan loads to ensure efficient transport, minimizing damage and maximizing space utilization. This includes understanding weight distribution and securement techniques.

- Communication and Teamwork: Highlight your skills in effective communication with colleagues, supervisors, and other stakeholders. Yard spotting often involves coordinating with multiple teams, emphasizing the importance of clear and concise communication.

- Problem-Solving and Decision-Making: Be ready to discuss instances where you faced challenges in a similar role and how you effectively resolved them. Focus on your analytical skills and ability to think on your feet in demanding situations.

- Inventory Management and Tracking: Understanding the importance of accurate inventory tracking and its impact on overall yard efficiency. Discuss different methods and technologies used for inventory management.

Next Steps

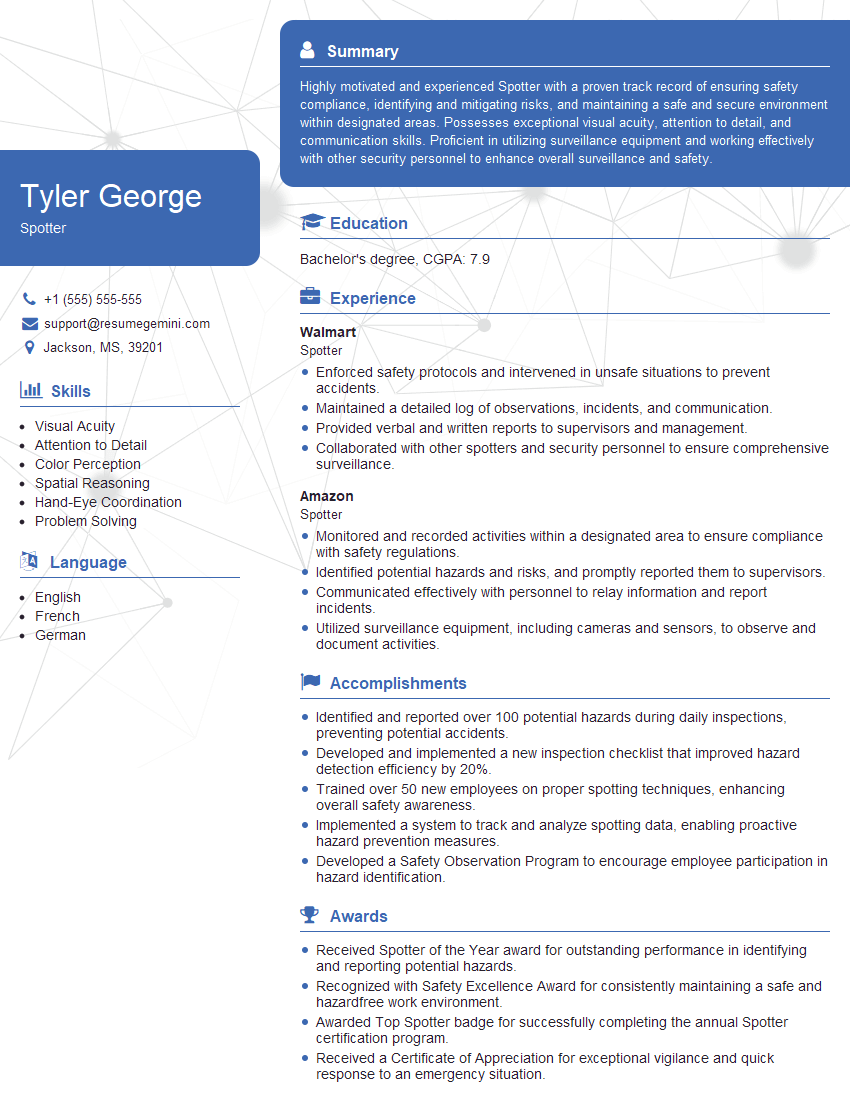

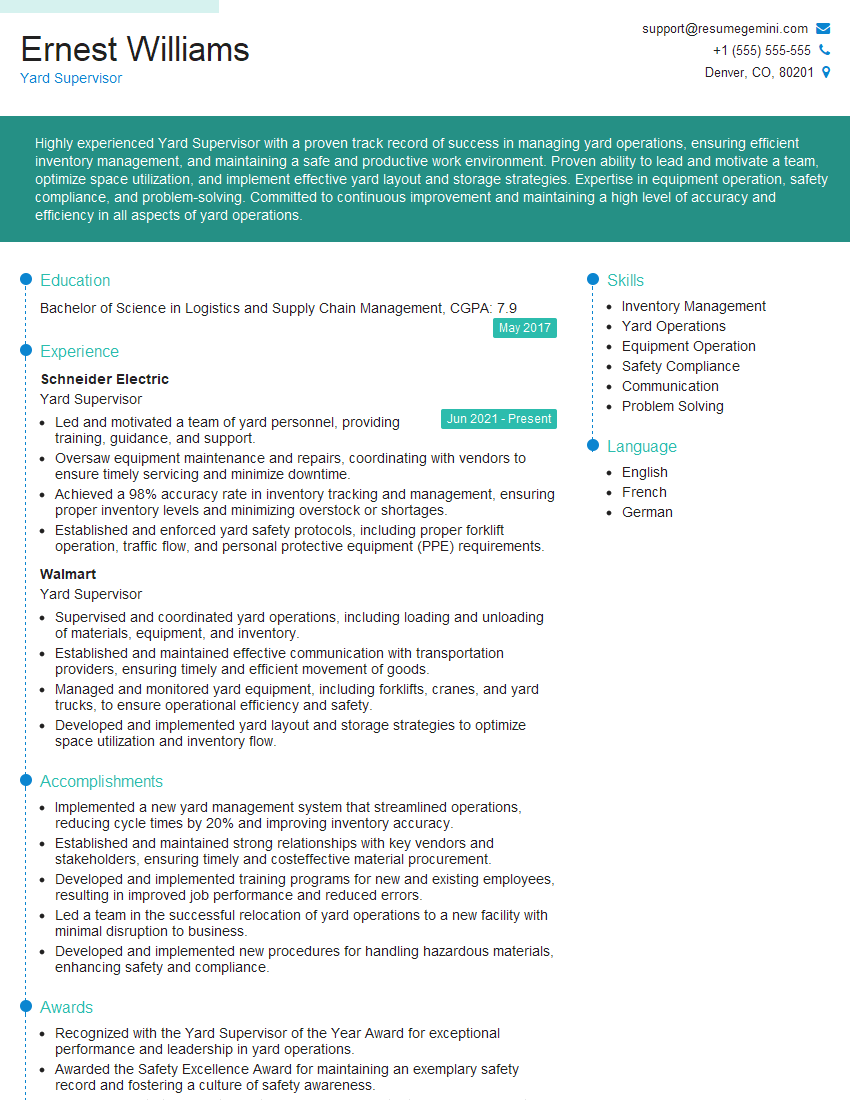

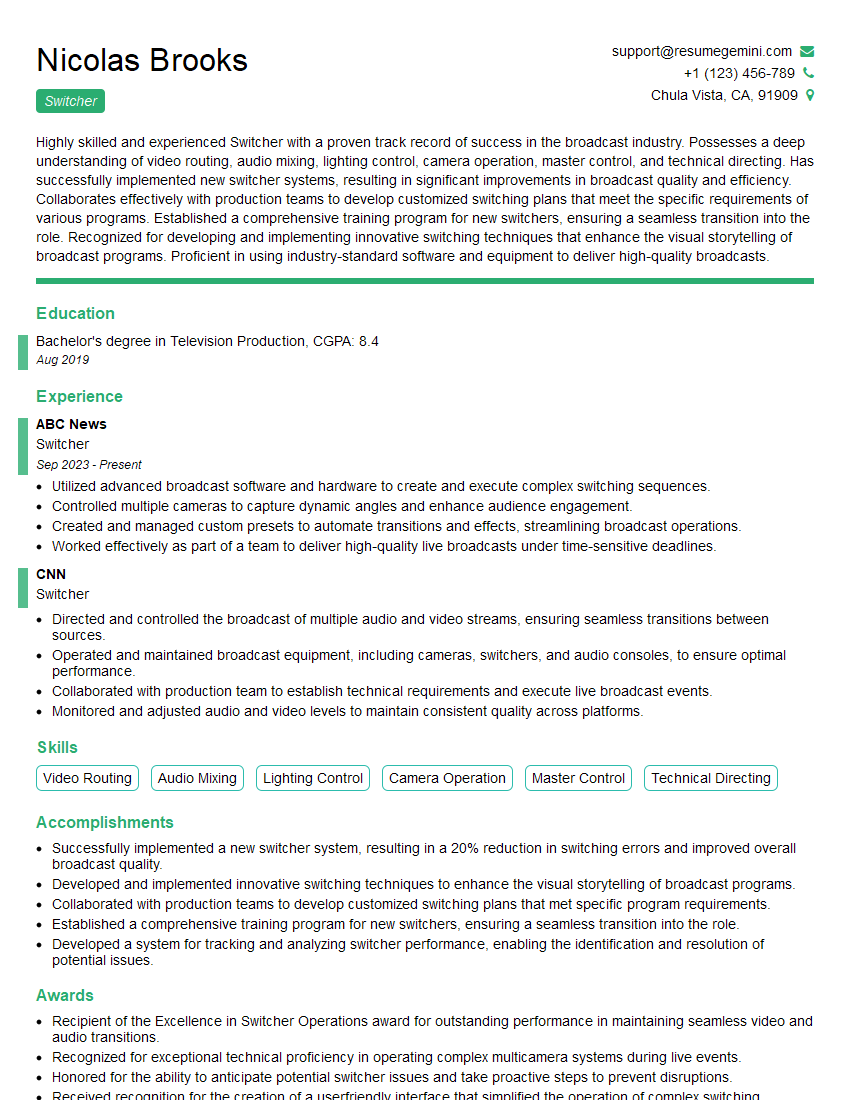

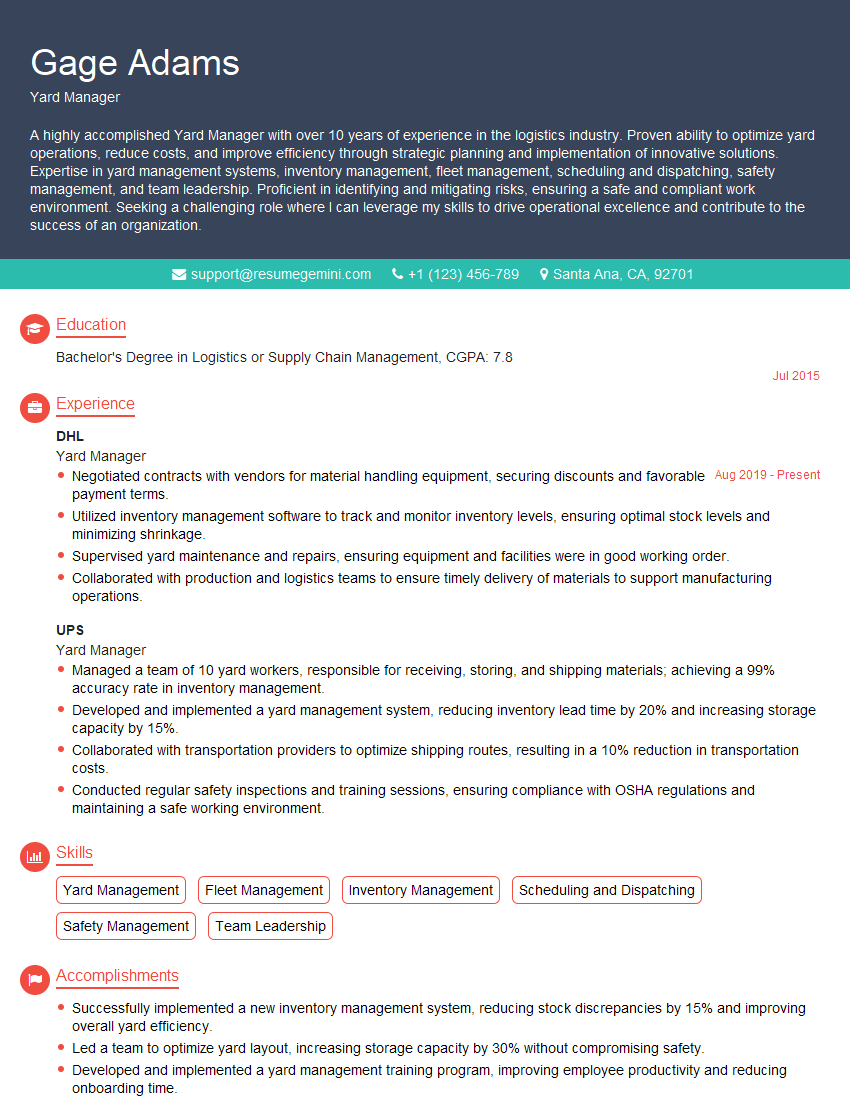

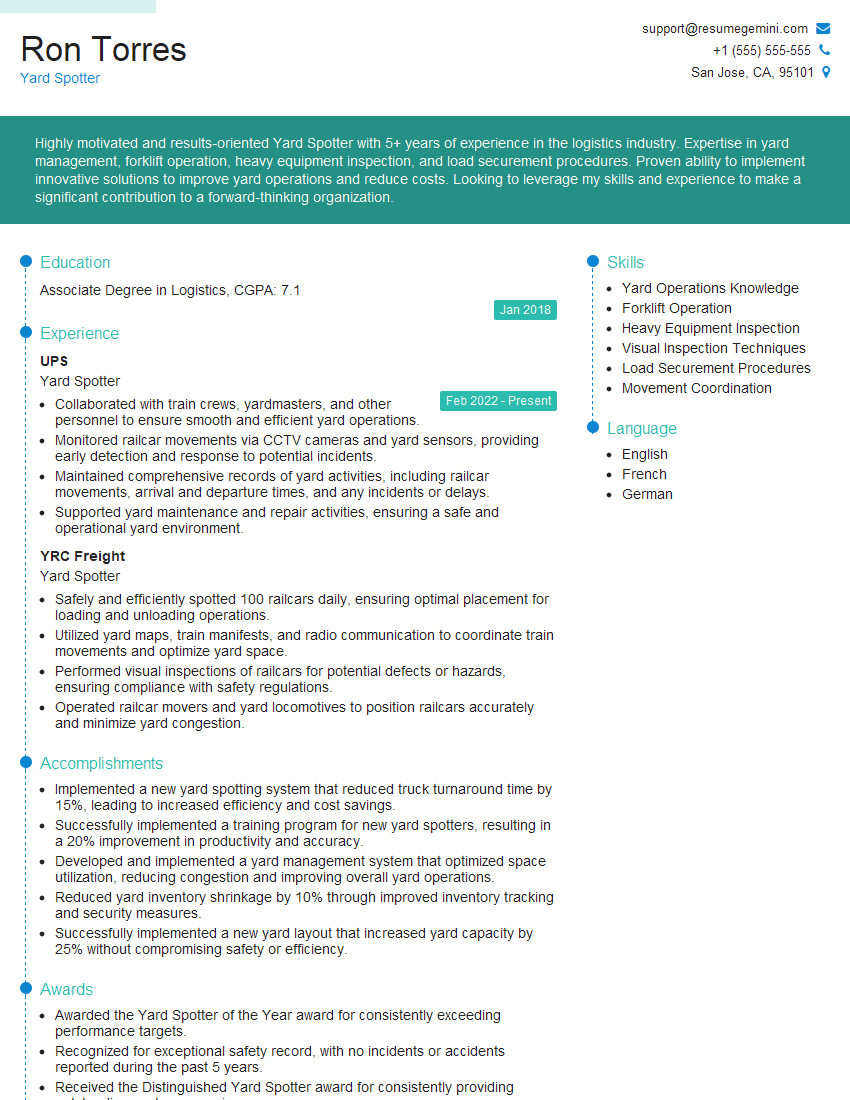

Mastering yard spotting skills opens doors to rewarding careers with excellent growth potential in logistics and transportation. To increase your chances of landing your dream job, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume that effectively showcases your skills and experience. Examples of resumes tailored to the Yard Spotting industry are available to help guide your resume creation process, ensuring it highlights your unique strengths and makes you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO